Extreme weather is no longer an exception—it’s becoming the new normal. In 2025, Europe experienced a record heatwave. Rooftop temperatures rose above 75°C in places like France, Italy, and Spain. These intense conditions pose serious challenges for rooftop solar installations, especially in terms of structural safety and material durability.

As the climate crisis deepens, solar mounting systems and stainless steel fasteners are being pushed to their limits. Their ability to handle heat, UV light, and rust decides if a solar project will last for decades or fail early.

Suzhou Bilateral Import & Export Co., Ltd. is a global supplier of stainless steel fasteners and aluminum solar mounting structures. They provide solutions designed to work in extreme environments. This helps ensure the long-term success of solar projects.

1. Why Heatwaves Threaten Solar Installations

When solar systems are installed on rooftops or in open fields, they’re directly exposed to the elements. In heatwave conditions, these three risks are most severe:

| Threat | What Happens | Impact |

|---|---|---|

| Thermal Expansion | Rails and modules shift or warp | Structural instability |

| Fastener Corrosion | Bolts loosen or break down | Falling modules, fire risk |

| UV + Humidity | Accelerated material aging | Shorter system lifespan |

Even with high-quality solar panels, a weak structural foundation can lead to major system failure. That’s why it’s critical to use heat-resistant, anti-corrosion mounting systems and fasteners.

2. The Role of Aluminum Mounting Systems in Heat-Resistant Design

Suzhou Bilateral produces aluminum mounting systems made from 6063-T5 industrial-grade profiles, treated with anodizing ≥12μm. This process enhances corrosion resistance and protects against high heat and UV degradation.

Key Mounting Components:

| Component | Material | Surface Treatment | Function |

|---|---|---|---|

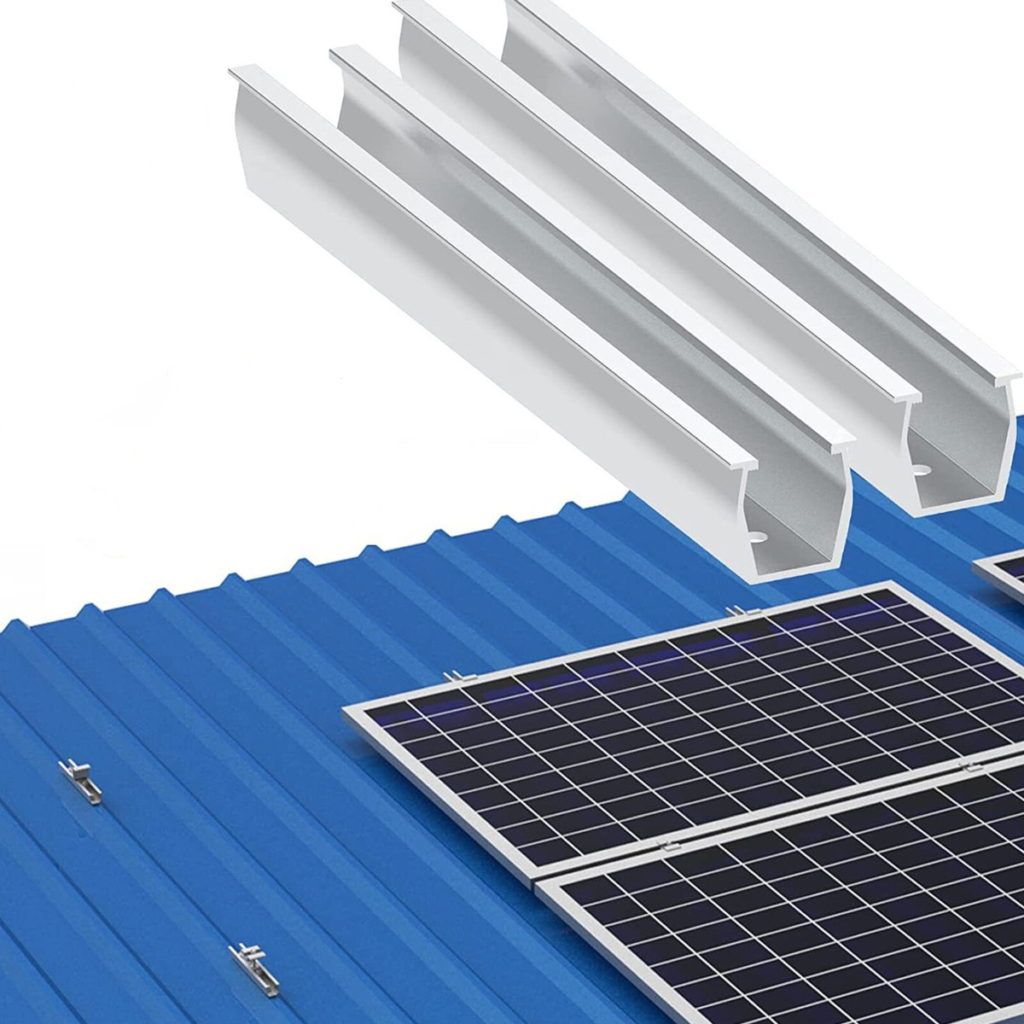

| Rail Profiles | 6063-T5 Aluminum | Anodized | Structural support for PV modules |

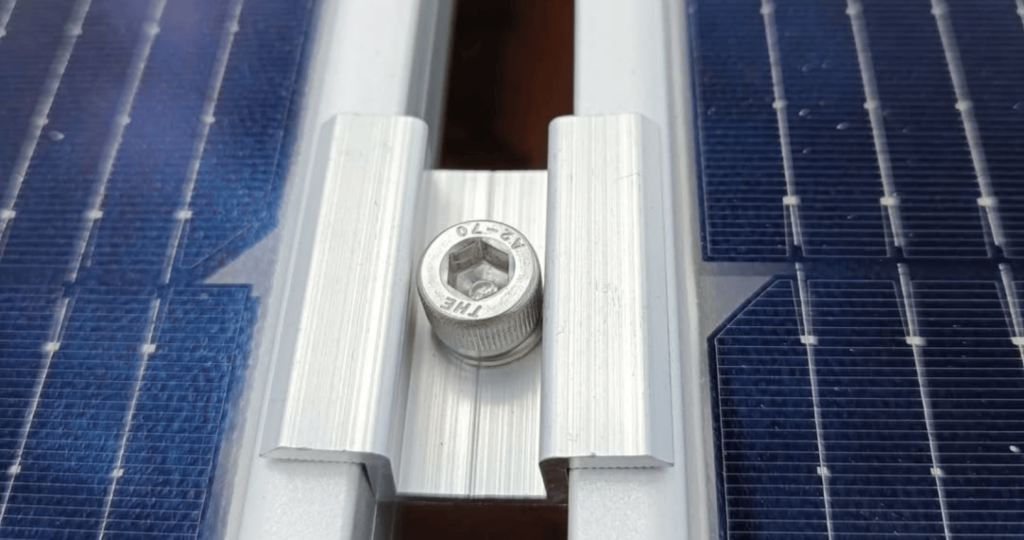

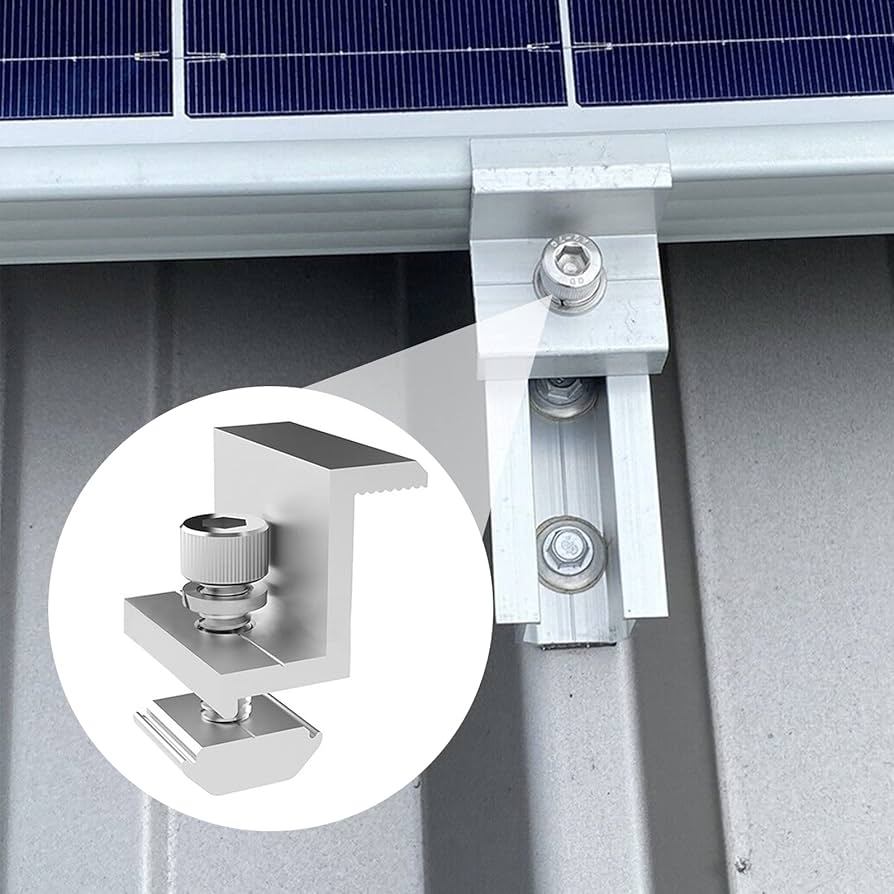

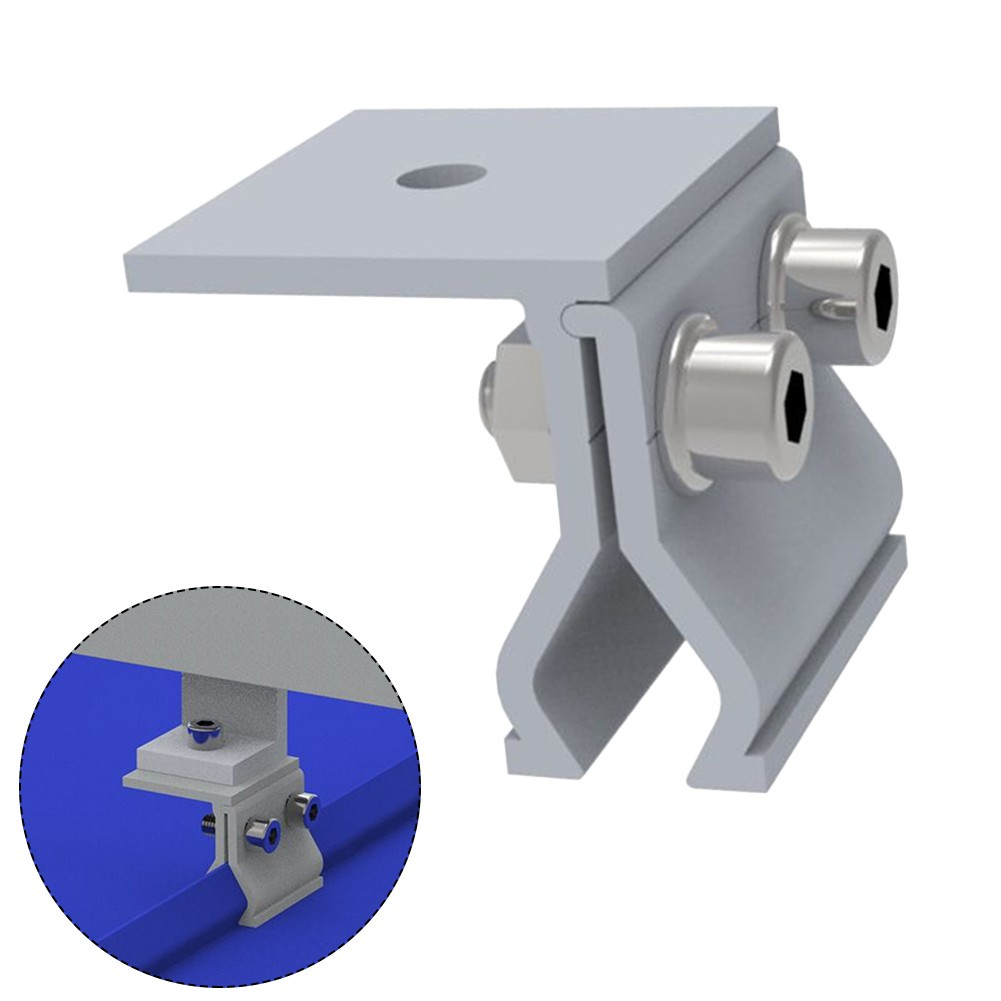

| Mid Clamps | Aluminum + EPDM | Anodized | Secure modules from the center |

| End Clamps | Aluminum | Anodized | Fix the outer edges of panels |

| Support Brackets | Aluminum / Steel | Anodized / Galvanized | Add tilt and elevation |

| Connection Plates | Aluminum / Steel | Dacromet / HDG | Reinforce structure at junctions |

Anodized aluminum is lightweight, rustproof, UV-resistant, and ideal for rooftop or coastal environments.

3. Stainless Steel Fasteners: Small Parts, Big Performance

Fasteners may be small, but they hold everything together. Suzhou Bilateral offers many stainless steel fasteners. They are made to work well in high temperatures, salt spray, and UV light.

Common Fasteners in Solar Projects:

| Fastener Type | Material | Surface Finish | Purpose |

|---|---|---|---|

| Hex Bolts & Nuts | SUS304 / SUS316 | Passivation | Frame and rail connections |

| T-Bolts + Nuts | SUS304 | Polished | Fast PV panel mounting |

| Self-Tapping Screws | SUS410 / Carbon Steel | Dacromet | Metal roof installation |

| U-Bolts & Threaded Rods | SUS304 / HDG Steel | HDG / Zinc | Pipe mounting or anchoring |

| Flange Nuts / Lock Washers | SUS304 / Carbon | Zinc / Oxidized | Prevent loosening under stress |

Coatings like Dacromet, HDG, or passivation extend fastener life up to 20+ years, even in harsh climates.

4. Complete Component Overview for Solar Projects

A robust solar mounting system is more than just rails. Here’s what most solar installations include:

Essential Components in Solar Systems

| Category | Components | Function |

|---|---|---|

| Mounting Structure | Rails, Support Legs, Brackets | Support and angle adjustment |

| Panel Fixings | Mid/End Clamps, Clips | Secure PV panels in place |

| Fasteners | Bolts, Screws, Nuts, Washers | Hold every piece together |

| Base Anchoring | Roof Hooks, Ground Bolts | Connect structure to base |

| Grounding Parts | Lugs, Ground Clips, Copper Bars | Electrical safety and lightning protection |

Configuration by Environment:

| Project Type | Recommended Materials | Fastener Strategy |

|---|---|---|

| Rooftop (Metal / Tile) | Anodized Aluminum | SUS304 + Dacromet Screws |

| Ground-Mount Solar | HDG Steel Structures | SUS316 + Hot-Dip Threaded Rods |

| Coastal Projects | Aluminum with SS Anchors | Duplex S32750 + Salt-Resistant Coating |

| Industrial BIPV | Reinforced Aluminum | Lock Nuts + Anti-Loosening Washers |

5. Suzhou Bilateral’s Product Range & Surface Treatments

With a 12,000 m² factory and full in-house processing, Bilateral provides turnkey component solutions for solar mounting needs.

| Product Line | Materials | Surface Finishes | Applications |

|---|---|---|---|

| Mounting Rails / Clamps | 6063 Aluminum | Anodized | Rooftop, Carport, Ground-Mount |

| Fasteners | SUS304 / 316 / 410 / S32750 | Passivation / Dacromet / Zinc / HDG | Solar Frame Assembly |

| Custom Parts (CNC) | Stainless / Steel | Sandblasting / Black Oxide | Special Projects, OEM |

All products undergo quality checks, including salt spray testing, tensile testing, and torque verification.

6. How to Choose the Right Supplier for Mounting & Fasteners

What to look for when sourcing solar hardware:

| Selection Factor | Why It Matters |

|---|---|

| Material Quality | Prevents rust, ensures lifespan |

| Surface Finish Options | Adapts to diverse environments |

| Delivery Speed | Avoids project delays |

| Component Integration | One-stop solutions simplify installation |

| Testing & Certifications | CE, ISO 9001, RoHS, QC pass reports |

7. Suzhou Bilateral: Built for Performance, Trusted Worldwide

With decades of experience and international customers in over 60 countries, Suzhou Bilateral offers:

- Full in-house manufacturing: CNC, anodizing, Dacromet, cold forging

- 10,000+ standard SKUs and rapid custom prototyping

- Advanced testing: salt spray, torque, tension, spectrometer

- 72-hour delivery for stock items, fast sample dispatch

- Certified by ISO 9001, CE, RoHS

8. Project Examples: Built to Last in Extreme Heat

| Location | Project Type | Challenge | Products Used | Result |

|---|---|---|---|---|

| Marseille, France | Rooftop Commercial Solar | 75°C Surface Heat | SUS316 Fasteners + Anodized Rails | 2 years no loosening |

| Valencia, Spain | Factory BIPV Roof | High Heat + Humidity | T-Bolts + Lock Washers + Dacromet Screws | Fast install, low maintenance |

Conclusion: Strength in Structure, Confidence in Climate

The transition to solar energy requires not only high-efficiency panels, but also high-performance structural systems. In hot weather and extreme climate conditions, mounting systems and fasteners play a crucial role. They are the unsung heroes who ensure solar installations are safe and function properly.

Suzhou Bilateral delivers engineered solar hardware to meet these challenges head-on—with quality, durability, and global expertise.

📞 Contact Us for Samples or a Quote:

🌐 Website: www.szbolts.com

📧 Email: sales@szbilateral.com