1. Introduction

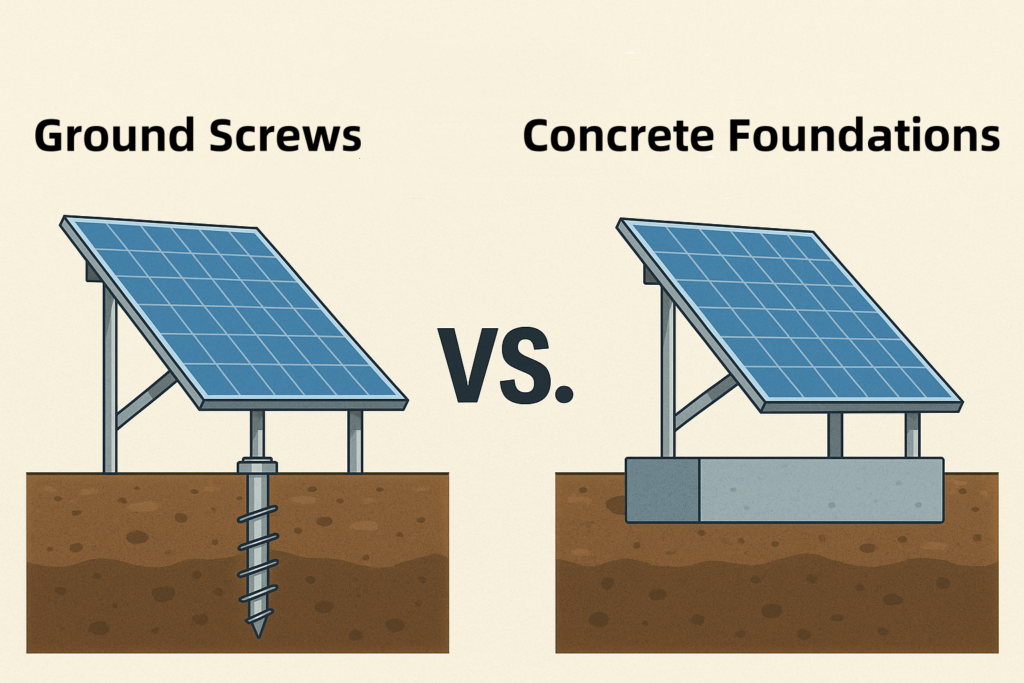

In any solar mounting system, the foundation is the backbone of the entire structure. It affects not only the system’s stability and durability but also installation speed and long-term maintenance. Two of the most commonly used foundation types are ground screws and concrete foundations.

But which one is the better fit for your solar project?

This article will compare both options across key factors like installation time, cost, terrain adaptability, reusability, and environmental impact to help you make the right choice.

2. What Are Ground Screws and Concrete Foundations?

A. Ground Screws

Ground screws are metal anchors with helical threads that are screwed directly into the ground using machinery. They are typically made from hot-dip galvanized steel or stainless steel and are designed to provide strong support without the need for excavation or concrete pouring.

They’re widely used for residential solar systems, off-grid installations, sloped terrain, and temporary solar setups.

B. Concrete Foundations

Concrete foundations include poured-in-place footings, precast blocks, or concrete pads. These require excavation, rebar placement, and a curing process.

They are ideal for large-scale solar farms, flat ground, and long-term installations where maximum stability is required.

3. Key Comparison: Ground Screws vs. Concrete Foundations

A. Installation Time & Labor

Ground Screws: Quick to install with minimal machinery; no curing time required. Perfect for projects with tight timelines.

Concrete Foundations: Time-consuming due to excavation, formwork, pouring, and curing. Requires more skilled labor and heavy equipment.

B. Cost Considerations

Ground Screws: Higher upfront material cost but lower labor, transport, and time costs. Often more economical overall.

Concrete Foundations: Lower material cost but higher costs for labor, equipment, and site preparation. Harder and costlier to remove later.

C. Environmental Impact

Ground Screws: Minimal soil disturbance, reusable, low carbon footprint—ideal for eco-conscious projects.

Concrete Foundations: Higher CO₂ emissions due to cement usage and site disruption. Not eco-friendly.

D. Load Capacity & Durability

Ground Screws: Durable and corrosion-resistant; suitable for small to medium solar systems.

Concrete Foundations: Very high load-bearing capacity; ideal for large installations or areas with strong winds or snow.

E. Terrain Adaptability

Ground Screws: Excellent performance on uneven, sloped, or soft terrain like sand or clay.

Concrete Foundations: Best for flat and stable terrain with easy equipment access.

F. Reusability & Relocation

Ground Screws: Fully removable and reusable—perfect for temporary or mobile installations.

Concrete Foundations: Permanent structure—difficult and expensive to remove or relocate.

4. When Should You Choose Ground Screws?

Projects on uneven or unstable terrain

Temporary or mobile solar setups (agriculture, off-grid, event-based)

Short construction timelines

Projects with strict environmental requirements

Locations with limited access for large machinery

5. When Should You Choose Concrete Foundations?

Large-scale solar farms with long-term operation

Locations with high wind or snow loads

Areas with stable soil and flat terrain

Projects where permits restrict ground screws

Sites with no need for future relocation

6. Real Project Examples

In a hillside agricultural solar project, ground screws allowed for fast, non-invasive installation on sloped land. The team saved over 30% in installation time and avoided soil excavation altogether.

In contrast, a large coastal solar farm used concrete foundations to ensure maximum structural stability against typhoon-level winds, making long-term durability the top priority.

7. Final Comparison Table

| Feature | Ground Screws | Concrete Foundations |

| Installation Time | Fast, no curing | Slow, needs excavation and curing |

| Overall Cost | Lower total cost | Higher due to labor and equipment |

| Environmental Impact | Eco-friendly, reusable | High carbon footprint |

| Load Capacity | Medium to high | Very high |

| Terrain Flexibility | Excellent (slope, sand, clay, etc.) | Limited (flat and accessible land) |

| Reusability | Removable and reusable | Permanent and non-recyclable |

8. Conclusion: Which Is Better for Solar?

There is no one-size-fits-all answer. The ideal foundation for your solar project depends on:

- Site terrain and soil conditions

- Project size and load requirements

- Budget and labor availability

- Installation timeline

- Environmental goals

For flexible, fast, and eco-friendly projects, ground screws are often the better choice. For large, permanent, and heavy-load systems, concrete foundations may offer unmatched stability.

When in doubt, consult with an experienced solar mounting supplier like SZ Bilateral, who can guide you to the best foundation based on your project conditions.

Need Help Choosing the Right Foundation?

At Suzhou Bilateral, we specialize in solar mounting solutions and stainless steel fasteners that meet the diverse needs of solar professionals worldwide. Our factory covers over 12,000 square meters, with more than 150 skilled workers and a monthly capacity of 5 million pieces.

We offer:

High-Strength Ground Screws

Made from hot-dip galvanized or stainless steel (SUS304, SUS316), suitable for soft or sloped terrain.

➤ Available in customized lengths and diameters.

Solar Mounting Structures

Including aluminum rails, hooks,solar clamps,side clamps,middle clamps,channel steel, L-feet, and solar brackets for ground, rooftop, and carport systems.

Stainless Steel Fasteners

Bolts, nuts, washers, rivets, and self-tapping screws—all corrosion-resistant and built for solar environments.

OEM & Custom Fabrication Services

We support custom drawings, private labeling, and fast delivery for global customers.

We work closely with EPCs, installers, and distributors across Europe, North America, Southeast Asia, and the Middle East, delivering products with ISO, CE, and SGS certifications.

Get in touch today for technical support or a free quote tailored to your project:

Email: sales@szbilateral.com

Website: www.szbolts.com

9. Frequently Asked Questions (FAQ)

Q1: Can ground screws work in clay or sandy soils?

A: Yes, with the right design and installation tools, ground screws perform well in various soil types.

Q2: Are concrete foundations better for large solar farms?

A: Yes, especially when structural stability and long-term performance are the top priorities.

Q3: Do I need permits for installing ground screws?

A: It depends on local regulations. Some areas may require soil testing or geotechnical assessments.