Self tapping screws are a versatile fastening solution. They are popular in construction, DIY projects, and metalworking. These screws drill their own holes as they are driven in-to materials.

However, using them incorrectly can lead to problems. Common mistakes can compromise the strength and stability of your project. Choosing the wrong type or size is a freq-uent error.

Understanding the differences between self tapping and self drilling screws is crucial. Each type has specific applications and benefits. Proper preparation of materials is also essential.

Over-tightening can strip threads and weaken joints. Using the right tools ensures a secure fit. This guide will help you avoid these common pitfalls.

Importance of Proper Use

Correct use of self tapping screws is vital for durability and safety.When used properly, these screws offer a strong and lasting hold.

Misuse can lead to project failures or costly repairs.Here are reasons proper use matters:

- Ensures structural integrity

- Prevents material damage

- Saves time and resources

Understanding these points can help you use self tapping screws effectively.

Overview of Self Tapping Screws

Self tapping screws are unique fasteners that create their own threads as they are driven into material. They are versatile and used in numerous applications, including metal, wood, and plastic.

This list highlights their key features:

- Ability to drill their own hole

- Variety of head styles and sizes

- Suitable for many materials

Understanding these features helps in choosing the right screw for your project. Proper selection ensures reliability and performance.

MISTAKE#1:CHOOSING THE WRONG SCREW TYPE

Choosing the wrong type of screw is a common mistake. Self tapping screws come in many forms, and not all are suitable for every job. Selecting a screw that is inappropriate for the material can result in weak connections or damage.

Factors to consider include the material’s thickness and hardness. Using metal tapping screws meant for thin metal on thick steel won’t work effectively. Also, the environmentplays a role. For outdoor applications, stainless steel self tapping screws resist corrosion much better.

Here’s a list of considerations:

- Material type and thickness

- Environmental conditions (indoor vs. outdoor use)

- Specific application requirements

Understanding these factors ensures you select the right fastener.

Self Tapping vs. Self Drilling Screws

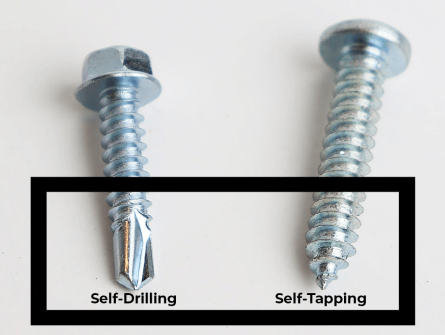

Confusing self tapping screws with self drilling screws is a frequent error. Both serve different functions. Self drilling screws, also known as self tapping self drilling screws, incorporate a drill point, eliminating the need for a pilot hole.

Here’s a quick comparison:

- Self Tapping Screws: Require a pilot hole, ideal for precise applications.

- Self Drilling Screws: Feature a drill tip, suitable for quick metal connections.

Knowing their differences can save time and improve the project outcome.

The Role of Material (Metal vs. Steel)

The material you work with influences screw selection significantly. Metal self drilling screws are generally suited for lighter metals. But, if you’re dealing with steel, use self tapping bolts for steel to ensure secure fastening.

Steel demands screws designed for its density. Using self tapping screws for metal on steel often leads to suboptimal results. Always match the screw type to the material to achieve a sturdy, lasting bond.

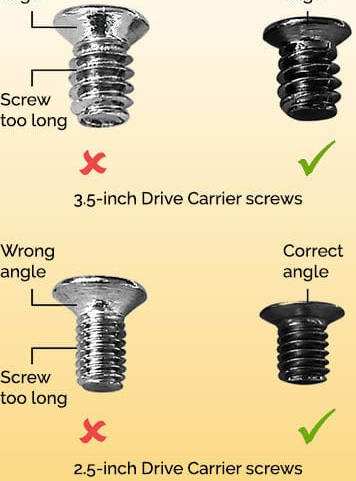

MISTAKE#2:INCORRECT SCREW SIZE

Using the wrong size of self tapping screws can lead to weak joints and potential failure. A screw that’s too short may not hold the material together firmly. Conversely, a long self tapping screw can damage surrounding structures.

Selecting the correct screw size involves considering the thickness and type of materials.For instance, big self tapping screws are ideal for thick materials, while small self tapper screws suit delicate items.

Here’s a list of factors to keep in mind when selecting screw size:

- Material thickness and type

- Load-bearing requirements

- Installation conditions

By ensuring the right size, you avoid unnecessary complications and ensure the strength of your connection.

How to Choose the Right Size

Choosing the right screw size involves multiple factors.First,assess the material’s thickness.Self tapping screws for metal differ significantly from self tapping screws for steel.

Consider these steps for proper selection:

- Measure the material thickness.

- Match the screw length accordingly.

- Evaluate the load requirements and select a screw that meets them.

Adhering to these guidelines guarantees effective and long lasting results in any application.

Considerations for Long and Small Self Tapping Screws

When deciding between long and small self tapping screws, consider the project specifics. Long screws offer greater holding power and are suited for thick materials. But they can be overkill for thin sheets or delicate work.

Small screws are excellent for projects needing precision and are less likely to cause damage. Balance is vital: choose a screw length that secures without overwhelming the material. This careful choice ensures success whether for a minor repair or substantial assembly.

MISTAKE#3:FAILING TO PREPARE THE MATERIAL

Not preparing the material before using self tapping screws can lead to poor fastening.Without proper preparation,the screw might not penetrate properly,potentially causingslippage or misali-gnment.

Different materials react differently to self tapping screws.Metal to metal self tapping screws,forinstance,require extra care during preparation to ensure optimal fit.A well prepped material can handle the stresses better and provide a secure hold.

To prepare the material effectively, consider these steps:

- Clean the material surface.

- Ensure the surface is flat and even.

- Use a guide, like a marker, for precise screw placement.

Proper preparation ensures the screw engages correctly,providing a robust and reliableconnecti-on.

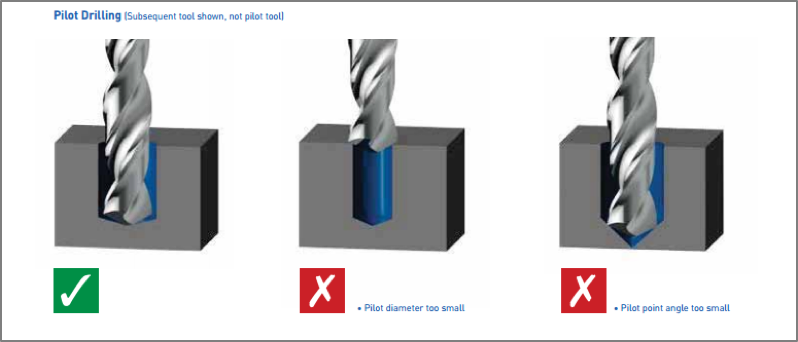

Importance of Pilot Holes

Drilling pilot holes is crucial when working with self tapping screws.A pilot hole guides the screw,helping prevent splitting and ensuring a straight path.

When a pilot hole isn’t used,especially in hard materials,it increases the risk of damage.Here’s why pilot holes matter:

- They reduce material stress.

- They ensure alignment, enhancing stability.

- They make screw insertion easier.

A correctly drilled pilot hole can significantly improve the final outcome, saving time and ensuring durability.

Impact on Stainless Steel Self Tapping Screws

Stainless steel self tapping screws are known for their durability and corrosion resistance.They excel in various environments,including marine applications.

However,failing to prepare stainless steel with a pilot hole can lead to threading problems.This oversight may result in a compromised connection.

In essence,even though these screws are tough,preparation is crucial.This effort can prevent unnecessary issues and prolong the screw’s life.

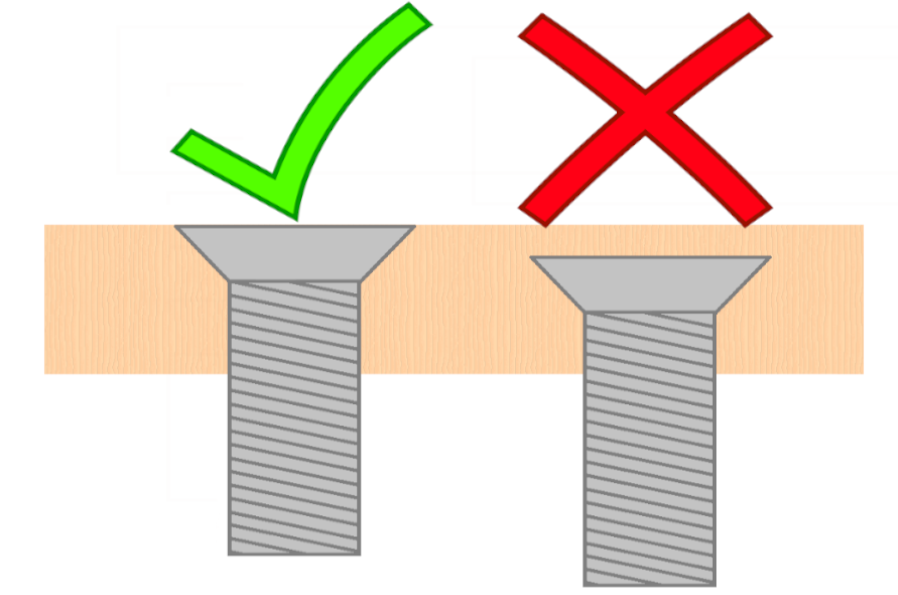

MISTAKE#4:OVER-TIGHTENING SCREWS

Over-tightening self tapping screws is a common error that can compromise the structure’s integrity. This mistake often results in stripped threads, reducing the fastener’s effectiveness. When threads are stripped, they no longer hold the material securely, which can lead to joint failure.

Moreover, excessive torque can damage the material around the screw. It may cause cracks, especially in brittle surfaces. The impact is not always immediately evident but can weaken the joint over time.

To prevent these issues, consider these guidelines:

- Use a torque wrench to measure force.

- Stop tightening when resistance is felt.

- Practice to develop a feel for the right tightness.

These strategies can help maintain the strength and reliability of your project.

Consequences of Over-Tightening

Over-tightening can lead to several detrimental effects. The most significant is the weakening of the connection, which defeats the purpose of using a screw. This can leadto structural failures or require additional repairs.

Some of the specific problems include:

- Thread stripping, which reduces holding power.

- Material cracking, often seen in plastics or thin metal.

- Increased wear, reducing the life of the fastener.

Avoiding over-tightening ensures that your self tapping screws perform at their best.

Best Practices for Torque Application

Using proper torque is crucial for effective fastening. Applying the right amount enhances the strength and longevity of your joint. Practice makes perfect when gaugingthe right tightness.

Consider these best practices:

- Calibrate your torque tool regularly for accuracy.

- Start slowly and increase pressure incrementally.

- Learn the specific requirements for different materials.

By following these guidelines, you can ensure secure and reliable connections with self tapping screws.an ensure secure and reliable connections with self tapping screws.

MISTAKE#5:USING INAPPROPRIATE TOOLS

Using the wrong tools for self tapping screws can lead to installation problems. Inappropriate tools can damage both the screw and the material. A mismatch in tool and screw type often results in poor fastening and wasted effort.

Using manual tools like screwdrivers might seem feasible, but power tools often provide better control. Without the right tool, achieving the correct torque and alignment becomes difficult. Mismatched tools also increase the risk of over-tightening or under-tightening.

To avoid these issues, consider the following tool selections:

- Use a power drill for quick and efficient installation.

- Employ a torque wrench to maintain proper pressure.

- Select compatible drill bits for the screw material.

By aligning tools with your screw type, you ensure a secure and efficient installation every time.

Recommended Tools for Self Tapping Screws

Choosing the correct tools makes working with self tapping screws easier.The right tool aids in precise installation and prolongs both screw and material life.

Essential tools include:

- Power drills for fast driving.

- Torque wrenches to control force.

- Compatible drill bits for the material.

These tools help achieve a secure fit and avoid common installation errors.

Comparison of Steel Self Screws and Stainless Steel Tappers

Steel self screws are durable for heavy-duty tasks. They’re suitable for tough materials like steel itself. In contrast, stainless steel tappers provide excellent corrosion resistance. They work best in outdoor or marine settings.

Both serve different needs but share the goal of efficient fastening.

CONCLUSION

Avoiding mistakes with self tapping screws ensures a secure and durable finish. Proper tool use and screw selection are vital. By understanding these common errors, you can enhance your project’s quality and longevity. Using the right techniques will save both time and resources.

ABOUT US

Suzhou Bilateral Import & Export Co.,Ltd. is a professional manufacturer and exporter specializing in high-quality stainless steel fasteners and solar mounting accessories. With over a decade of industry experience, we are committed to delivering reliable solutions for global construction, photovoltaic, and industrial applications. Our factory is equipped with advanced production lines and a strict quality control system, ensuring every product meets international standards. Whether you need standard fasteners or customized solutions, Suzhou Bilateral is your trusted partner for strength, durability, and precision.

CONTACT MAIL:sales@szbilateral.com