In real-world engineering, washer misuse is surprisingly common—spring washers paired with high-strength bolts, flat washers that deform under pressure, and so on. These small mistakes can compromise the integrity of an entire fastening system. So how do you avoid costly errors when selecting washers? Let’s break it down clearly.

1. Spring Washers — Only for Specific Applications

- Spring washers are designed to prevent loosening under certain conditions, but their effectiveness can be greatly reduced by:

- Material Defects: Excessive hardness or improper heat treatment

- Mechanical Stress: Overloading or stress relaxation

- Environmental Factors: Exposure to high temperatures or corrosion

- Human Error: Incorrect installation

According to DIN 127, spring washers are suitable for use with medium or low-strength bolts/nuts (e.g., grade 5.8). They work well in non-critical joints with minimal lateral vibration. However, for high-frequency vibrations or long bolt assemblies, spring washers can become ineffective.

Current international and national standards rarely recommend spring washers in high-strength bolted joints.

Conclusion: Spring washers are best used in static assemblies with low preload requirements and minimal side loading.

Common Mistakes to Avoid with Spring Washers:

- Pairing with high-strength bolts (10.9/12.9 grade) — can flatten the washer under high preload

- Using on soft materials like aluminum can damage surfaces

- Reusing deformed washers — elasticity is compromised after first use

How to Choose Spring Washers the Right Way

Refer to GB/T 94.1-2008, which defines material properties, surface treatments, and testing requirements.

Material & Surface Treatment Overview:

| Material Type | Steel Grades | Heat Treatment | Hardness (HRC/HRB) | Surface Treatment |

| Spring Steel | 70, 65Mn, 60Si2Mn | Quenched & tempered | 40–50 HRC | Oxidation / Phosphating / Zinc Plating (GB/T 5267.1) / Zinc Flake Coating (GB/T 5267.2) |

| Stainless Steel | 30Cr13, 0Cr18Ni9, etc. | Tempered | ≥34 HRC | Simple Coating |

| Phosphor Bronze | QSi3-1 | — | ≥90 HRB | — |

⚠️ Hydrogen embrittlement treatment is mandatory after electroplating.

Key Performance Tests:

- Elastic Recovery Test: After 3 loading cycles, free height ≥ 1.67× nominal thickness

- Torsion Test: Twisted 90° — no visible fracture

- Hydrogen Embrittlement: Load held for 48 hours — no cracking allowed

2. Flat Washers — Must Match Bolt/Nut Strength

Flat washers are essential for distributing loads and protecting surfaces, especially where oversized holes or soft materials are involved. However, choosing the wrong hardness or size can lead to deformation, loss of preload, or uneven load distribution.

How to Evaluate Washer Hardness:

- Visual Clues: Washer edges deform or leave marks → likely too soft

- Testing: Use a hardness tester; for 8.8 grade bolts, washer hardness should be ≥ 200 HV

Washer Selection Must Match Fastener Grade

Below is a simplified version of washer-hardness matching based on GB/T standards:

| Washer Type | Standard | Hardness (HV) | Suitable Fastener Grades |

| Large Washer | GB/T 96.1 (A) | 200–300 | Grade 8.8 & 10.9 bolts/nuts |

| Flat Washer | GB/T 97.1/97.2 (A) | 200–300 | Grade 8.8 & 10.9 bolts/nuts |

| Flat Washer | GB/T 95 (C) | 100 | Grade 6.8 bolts/nuts, hardened thread-forming screws |

| Small Washer | GB/T 848 (A) | 200–300 | 8.8–10.9 socket/spline head screws |

| Oversized Washer | GB/T 5287 (C) | 100 | Grade 6.8 bolts/nuts (e.g. wood structures) |

Special Cases:

- Slotted holes: Use oversized or custom washers to prevent shifting

- Aluminum profiles: Stainless or zinc-nickel washers help avoid galvanic corrosion

- Electrical insulation: Nylon or PTFE washers recommended

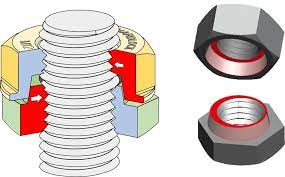

3. Advanced Anti-Loosening Technologies

While “flat + spring washer” setups solve basic loosening issues, they’re no match for heavy vibration or impact loads. In such cases, washers can permanently deform or lose friction.

Modern anti-loosening solutions go far beyond traditional washers and fall into three main categories:

Mechanical Locking

- Flange Nuts: Create strong static friction, ideal with high-strength bolts

- Nylon Lock Nuts: Nylon ring compresses into threads; vibration increases grip

- All-Metal Lock Nuts: Top section deforms elastically, maintaining clamping force

Chemical Locking

Threadlocker (Anaerobic Adhesive): Cures after application, locks threads securely

- Ideal for inaccessible joints or fine threads

- Different grades offer varying disassembly strengths (removable or permanent)

Structural Locking

Eccentric Self-Locking Nuts: Eccentric shape shifts thread forces to resist loosening

Slotted Lock Nuts: Pre-closed slot rebounds after tightening, creating locking tension

BONUS: High-Performance Washer Alternatives

Emerging high-end washer solutions include:

Serrated Lock Washers: Increase friction on coated or slippery surfaces

Wedge-Locking Washers (e.g., Nord-Lock): Dual-layer system with cam and radial teeth. Offers superior locking performance under extreme vibration or dynamic loading.

These are widely used in railways, wind power, and heavy-duty machinery.

Final Thoughts: Don’t Let the Small Parts Fail the Big System

In bolted connections, washers are often overlooked—but their failure can result in critical system issues. Whether you’re designing wind turbines, rooftop solar frames, or precision machinery, washer selection deserves serious attention.

Always consider:

- Application scenario

- Load direction and vibration

- Bolt grade compatibility

- Material and surface interaction

- Anti-loosening requirements

Looking for reliable washer solutions?

We provide a full range of certified spring, flat, and lock washers—with engineering support to help you choose the right model for your project.

Contact us for technical advice or bulk ordering.

ABOUT US

Suzhou Bilateral Import & Export Co.,Ltd. is a professional manufacturer and exporter specializing in high-quality stainless steel fasteners and solar mounting accessories. With over a decade of industry experience, we are committed to delivering reliable solutions for global construction, photovoltaic, and industrial applications. Our factory is equipped with advanced production lines and a strict quality control system, ensuring every product meets international standards. Whether you need standard fasteners or customized solutions, Suzhou Bilateral is your trusted partner for strength, durability, and precision.

Contact mail: sales@szbilateral.com