Solar System Down After the Storm? Maybe It Wasn’t the Wind…

🌪️ From Russia’s tsunami alerts after a 7.4-magnitude quake, to Typhoon Co-may hammering the Pacific coast, and torrential rains soaking southern China—extreme weather is hitting harder and more often.

In this climate reality, rooftop solar systems face greater risks than ever. But when a solar installation collapses, is the wind really to blame?

Surprisingly, many system failures are caused not by natural forces themselves, but by human error, poor component selection, and overlooked installation details.

Strong Claims ≠ Strong Systems

With more frequent typhoons and seismic storms in Asia-Pacific, the demand for typhoon-resistant solar mounting systems has surged. But not all solutions are created equal.

True wind-resistant systems depend on:

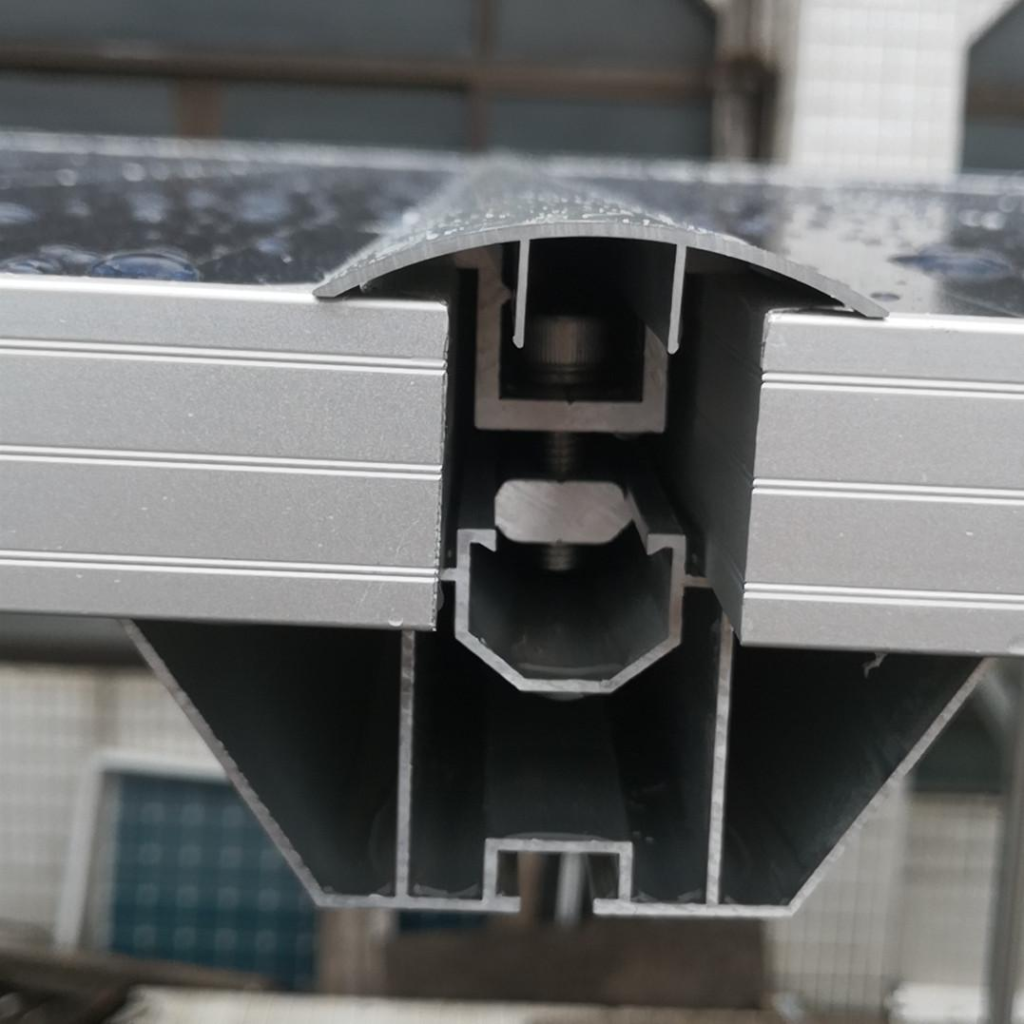

- Smart structural design – triangular bracing and reinforced rails reduce lateral movement.

- Reliable fasteners, such as double-threaded stainless steel screws with locknuts to prevent loosening.

- Roof anchoring that fits the surface – Metal roofs use double-threaded drill screws, and concrete roofs use expansion bolts. One cannot mess up, two cannot save

🌀 In regions recently hit by Typhoon Co-may, several poorly installed rooftop systems were reported to shift or collapse—most lacked thermal gaps and used inferior screws.

It’s not the strong wind—it’s the details you missed.

Heavy rainfall, sudden gusts, or even seismic tremors often expose hidden flaws in a mounting system:

- No expansion gaps → thermal stress causes cracking.

- Poor waterproofing → water weakens anchor points.

- Low-grade fasteners → corrosion leads to long-term instability.

- Undersized rail profiles → insufficient resistance under wind uplift.

If you’re in a typhoon or quake-prone zone, don’t assume your system is safe just because it’s “installed.”

A truly wind-resistant, durable PV system needs these key features:

Here’s what makes a solar system truly storm-ready in today’s climate:

| Feature | Recommendation |

|---|---|

| Mounting Material | Anodized aluminum (≥15μm) or 304 stainless steel |

| Fasteners | Double-threaded screws with locking nuts |

| Anchoring Method | Drilling screws (metal roof) or expansion bolts (concrete) |

| Structural Design | Triangular supports, cross bracing |

| Installation Details | Waterproof pads, thermal expansion gaps |

| Environmental Adaptation | Designed for local wind, seismic & flood risks |

Is your system truly ready for extreme weather?

It’s not that the wind is too strong—it’s that the system is too weak.

Wrong brackets, the wrong screws, or neglected details can render even the sturdiest solar panels useless.

As typhoons and heavy rains peak, now’s the time to check your system, especially if:

- You’ve noticed looseness, shifting, or water leaks

- Your roof is made of metal sheets or lightweight materials

- It’s been over 5 years since installation, with no inspection

Act now: Make sure your fasteners and mounting structures are built to withstand your local climate.

Who We Are

At Suzhou Bilateral Import & Export Co., Ltd, we engineer solar mounting systems and stainless steel fasteners for the real world, where typhoons, earthquakes, and torrential rain are no longer rare.

Our strengths:

- Double-threaded solar screws for metal roofs

- High-grade 304/316 stainless steel bolts

- Anti-corrosion anodized aluminum rails

- Structural brackets tested for wind loads

- Full system support for seismic zones

Whether you’re in coastal Japan, southern China, or anywhere in the storm path, we’ll help you build it stronger, smarter, and safer.

📩 Contact us at sales@szbilateral.com for tailored solutions based on your location and risk level.