Did you know? A single overlooked fastener could put your entire solar investment at risk—leading to unexpected leaks, weak mounting, or costly repairs. While most homeowners focus on panels and inverters, solar hanger bolts are the invisible heroes that keep your rooftop solar system safe, strong, and leak-free for decades.

In this guide, you’ll discover:

- What makes solar hanger bolts essential for every rooftop PV system

- The different types—so you choose the perfect bolt for your roof and climate

- Step-by-step installation tips to eliminate common mistakes and save money

- Leading standards, load capacity, and top FAQs every solar owner should know

Whether you’re installing solar panels on a suburban house, office building, or challenging coastal property, this article provides the keys to trouble-free, durable solar mounting.

What Is a Solar Hanger Bolt—and Why Does It Matter?

Solar hanger bolts are dual-purpose fasteners, custom-designed for rooftop solar. With wood threads on one end and machine threads on the other, they securely anchor PV racking to timber rafters, steel purlins, or metal sheets—while also protecting your roof from water intrusion. They transfer the force of wind, snow, and panel weight safely into your building structure.

Key Benefits:

Decades-long reliability even under tough conditions

Prevents panels from shifting or detaching in storms

Ensures watertight penetration—no more leaks

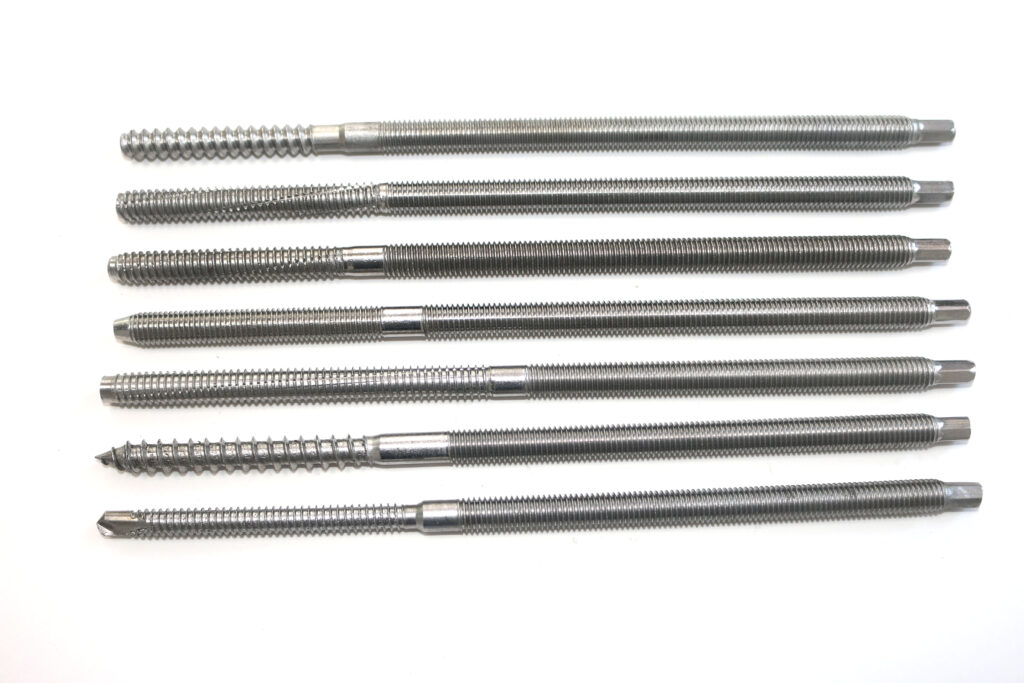

Types of Solar Hanger Bolts (How To Choose the Best Fit)

Wood-thread solar hanger bolt

This is the most common type, designed for pitched roof installations where timber rafters are present. The deep wood threads deliver strong pull-out resistance and long-term reliability.

Practical example: Residential rooftops in suburban areas often use this type, as most houses rely on timber framing.

Solar Hanger Bolt(Sharp Point with Coarse Thread)

Commonly Used: Wood/Softwood

What’s Special

- ST8 can effectively prevent wood from cracking during installation.

- ST3/8 applies to most softwoods, but you must create reserved holes before installation.

Solar Hanger Bolt(Self-Drilling)

Commonly Used: Metal Roof

What’s Special: It can be installed directly into metal sheets without pre-drilling. Can save labor costs. When used on wooden structures, a pre-drilled hole is required.

Flat-End Solar Hanger Bolt

This version is designed to sit flush with adapter plates, preventing unnecessary protrusion above the roof surface. It is often used where aesthetics or space constraints are important.

Practical example: Buildings with visible rooftop solar systems—such as schools or office buildings—benefit from flat-end designs to maintain a neat appearance.

Solar Hanger Bolt (Flat end with relief groove)

The Relief Groove design provides additional benefits: it distributes stress more evenly, reduces the risk of timber cracking, and improves the waterproof seal around the bolt. This makes it the preferred choice for heavy-duty applications in demanding environments.

Practical example: Solar arrays in coastal regions or alpine climates, where strong winds and heavy snow are common, typically adopt this type to ensure extra safety and durability.

Solar Hanger Bolt(Fine Thread with Sharp Point)

What’s Special: Pre-drilling required. Enhanced thread grip delivers a stronger, more secure fastening.

| Type | Application | Features/Benefits |

|---|---|---|

| Wood-thread Solar Hanger Bolt | Pitched roofs, timber rafters | Strong grip, pull-out resistance |

| Sharp Point w/ Coarse Thread | Wood/Softwood (ST8, ST3/8) | Crack prevention, easy install |

| Self-Drilling Solar Hanger Bolt | Metal roofs, steel purlins | No pre-drilling, labor-saving |

| Flat-End Solar Hanger Bolt | Visible rooftops, space constraints | Flush fit, aesthetic finish |

| Relief Groove Flat-End | Heavy-duty, harsh climates | Even stress, better sealing |

| Fine Thread w/ Sharp Point | Wood (pre-drilled) | Enhanced thread grip |

Pro tip: Choose your bolt based on roof material, environmental stress, and aesthetics. SS304 for most urban/inland projects; SS316 for coastal or industrial roofs.

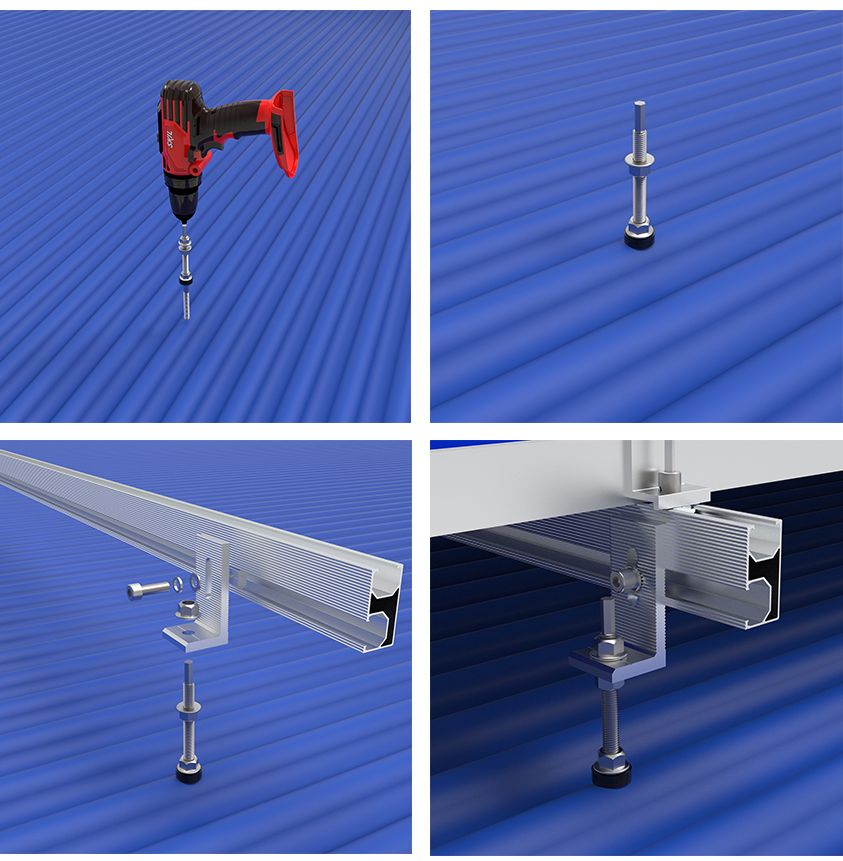

How Solar Hanger Bolts Work—Structure and Waterproofing

The hanger bolt’s wood thread buries deep inside rafters or purlins for secure attachment, while its machine thread sticks out above the roof for mounting L-feet or rails. Add EPDM washers, sealant, and flashing for a professional, leak-free installation that lasts.

All mounting pressure and exterior loads get distributed directly to the building’s strongest support members—keeping your solar secure and your roof bone-dry.

Step-by-Step Installation Guide (For Safety and Leak Prevention)

- Identify support rafters/purlins with a stud finder or plans

- Drill pilot holes for wood-thread bolts, preventing splitting

- Drive in the hanger bolt until snug, with correct embedment depth (≥60mm)

- Apply EPDM washers, flashing, and sealant at each penetration

- Mount brackets/rails securely to the machine-threaded end

- Tighten to the specified torque (e.g., 20–25 Nm for M10)

- Inspect waterproofing and structural stability for peace of mind

Mistakes to avoid: Anchoring to just roof decking, bolts too short/long, skipping waterproofing, overtightening, or using uncertified fasteners.

Material Choice & Standards—For Maximum Durability

Safety Factor: Always design load capacity with a safety factor of 3x or higher

Stainless Steel (SUS304, SUS316): The best for outdoor strength and no rust

International Standards: UL 2703, IEC 61730, ISO 9227—always choose certified fasteners for code and warranty compliance

Load Capacity Reference Table

Load performance depends on bolt size, embedment depth, and installation quality. Typical values include:

| Spec | Pull-Out Strength | Shear Strength | Working Load |

| M8 | 5–6 kN | 4–5 kN | ≤ 1.5 kN |

| M10 | 7–8 kN | 6–7 kN | ≤ 2.0 kN |

| M12 | 9–10 kN | 7–8.5 kN | ≤ 2.5–3.0 kN |

Always design with a safety factor of 3 or higher and ensure embedment of at least 60 mm into timber structures.

How to Choose the Right Bolt

Selecting the correct solar hanger bolt requires evaluating multiple factors:

Roof type:

- Wooden roofs (e.g, wooden beams/purlins) → wood-thread;

- Metal roofs (e.g, thin steel sheets/metal purlins) → self-drilling or flat-end.

Load requirements: Residential → standard bolts; Utility-scale → Relief Groove heavy-duty bolts.

Material environment: Inland → SUS304; Coastal/industrial → SUS316.

Aesthetic needs: Use flat-end bolts for low-profile or visually sensitive projects.

Certification: UL/TÜV/ISO ensures compliance and warranty protection.

By considering these factors, installers and EPCs can avoid mismatches and ensure both safety and cost efficiency.

Common Mistakes to Avoid

Anchoring into the roof decking only, instead of rafters or purlins.

Selecting bolts that are too short or excessively long.

Skipping waterproofing measures leads to leaks over time.

Over-tightening can damage threads or seals.

Using uncertified fasteners in projects where compliance is required.

These mistakes may seem small, but they often result in costly rework or warranty issues.

Suggestions for use

- Solar Hanger Bolt(Sharp Point with Coarse Thread): ST8 thread is used for wooden purlins, which can prevent the wood from cracking. ST3/8 is suitable for softwood, and a reserved hole is needed.

- Self-drilling solar hanger bolt can be used for both wooden and steel purlins. When used in wood, holes need to be reserved; otherwise, a lot of heat will be generated due to friction during use, which will lead to wood carbonization and even combustion, and destroy the wood structure and the screw itself.

- Both steel structure and flat tail need reserved holes to be installed, and both can be used in wood or metal in theory.

- It is suggested that the solar hanger bolt with a different pitch should be selected according to the back thickness of the roof tiles, and the matching solar hanger bolt should be selected according to the purlin material to avoid affecting the roof and system life.

Common FAQs

Q: Can solar hanger bolts be reused?

A: No—reused bolts lose grip and sealing. Always install fresh bolts.

Q: Relief Groove bolts—when to use?

A: Ideal for high-stress installs—extra load distribution and waterproofing.

Q: Best stainless steel grade?

A: SS304 (inland/urban), SS316 (coastal/industrial)

Future Trends

Pre-assembled hanger bolt kits for faster, safer installs

Smart bolts with torque monitoring for instant feedback

Next-generation alloys for sustainability and extreme environments

Conclusion: Your Secure Solar Starts Here

Solar hanger bolts are more than just small parts—they’re the foundation of rooftop safety and long-term solar success. With the right type, precise installation, and certified quality, you ensure decades of leak-free, worry-free clean energy.

Suzhou Bilateral Import & Export Co., Ltd. is committed to helping you build the safest and most durable PV mounting systems—offering all types of solar hanger bolts and technical advice for any project.

Ready to upgrade your solar reliability? Explore our Solar Mounting Products Catalog or request a free expert consultation today.