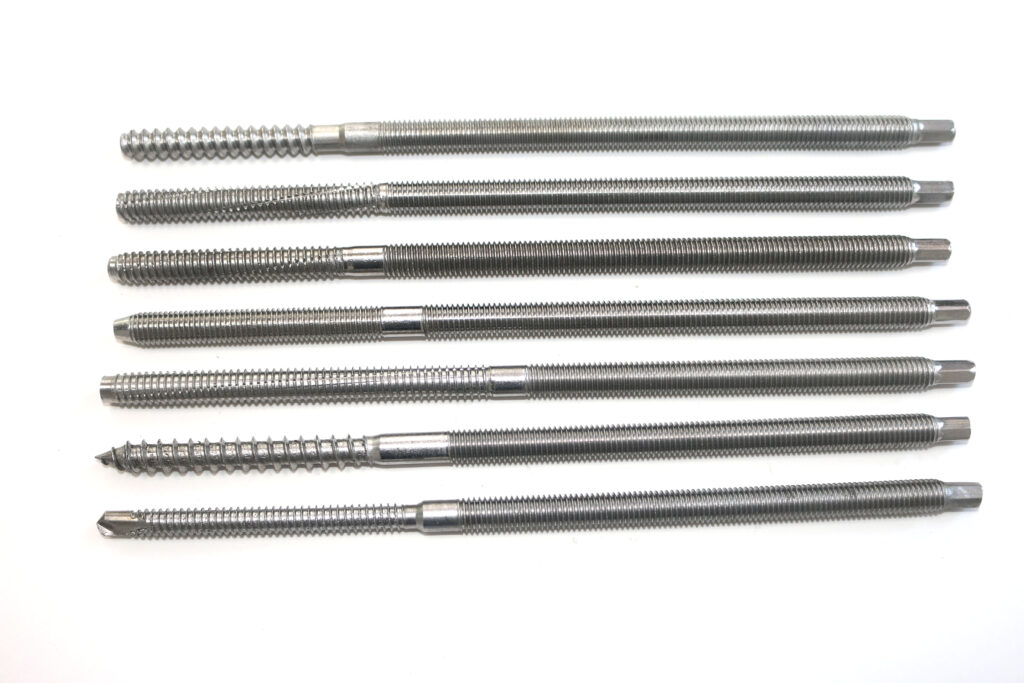

With the rapid growth of solar energy, the material of solar hanger bolts is now a crucial factor in system safety, reliability, and lifecycle cost. SUS304 and SUS316 are the top choices for stainless steel fasteners, each offering distinct advantages based on environment and project goals.

Why Does Hanger Bolt Material Matter?

The right fastener keeps PV mounting systems secure against wind, rain, and corrosion for 20+ years. A poor choice can lead to premature rust, instability, and costly repairs.

Understanding Stainless Steel in Solar Applications

Stainless steel protects itself with a thin passive film—key for fasteners exposed to moisture and pollutants. This self-healing layer is why stainless bolts are preferred for PV roof systems.

SUS304: Cost-Effective, Reliable for Mild Conditions

- Composition: ~18% chromium, ~8% nickel

- Strength: High mechanical strength, ductility, easy manufacturing

- Corrosion Resistance: Good in freshwater and open air; less effective in salt, acids, or chlorides

- Cost: Lower material and processing costs

- Best Use: Inland residential/commercial PV projects, mild climates

SUS316: Ultimate Protection for Harsh Environments

- Composition: 16-18% chromium, 10-14% nickel, 2-3% molybdenum

- Strength: Similar or better high-temperature, creep resistance

- Corrosion Resistance: Excellent against salt spray, humidity, acids, and pollutants

- Lifecycle Cost: Higher initial price, but lower maintenance and system downtime

- Best Use: Coastal, industrial, humid, or polluted areas; utility-scale or long-lifespan projects

SUS304 vs SUS316: Key Differences At a Glance

| Property | SUS304 | SUS316 |

|---|---|---|

| Alloys | Chromium, Nickel | Chromium, Nickel, Molybdenum |

| Chloride Resistance | Moderate; risk of pitting | Excellent; strong pitting resistance |

| General Corrosion | Good for mild climates | Superior in harsh environments |

| Strength | Strong, ductile, versatile | Similar, better at high temps |

| Cost | Lower | Higher |

| Application | Inland, dry, easy conditions | Industrial, coastal, humid, polluted |

This table highlights the essential performance differences and provides a clear reference for selection.

Which Should You Choose?

- Environment:

- Inland/mild regions: SUS304 for reliable performance and lower cost

- Coastal/industrial/humid: SUS316 for maximum corrosion protection

- Project Duration:

- Short-term/budget-focused: SUS304

- Long-term/lifecycle value: SUS316

Conclusion

There’s no universally superior grade—only the right choice for your project’s environment, lifespan, and budget.

- SUS304 offers value and strength for mild conditions.

- SUS316 delivers unmatched durability for challenging, corrosive environments.

For secure, long-lasting PV systems, select your hanger bolts carefully—ensuring project safety, reliability, and cost-efficiency..

Company Information

Suzhou Bilateral Import & Export Co., Ltd. is a professional supplier specializing in solar mounting systems and fastener solutions. Our flagship products include roof solar mounting systems and accessories such as solar hanger bolts, middle clamps, and side clamps. The product portfolio covers complete solar mounting systems and a wide range of solar accessories, widely applied in residential, commercial, and utility-scale PV projects.

With strict material selection standards and advanced manufacturing processes, our products are trusted by customers worldwide and have been exported to Europe, Southeast Asia, and the Middle East.

For more information, please visit: www.szbolts.com