1. Introduction

Are you concerned about water leaks after installing your rooftop solar system? Recent industry data shows that over 20% of photovoltaic projects experience leakage because of overlooked waterproofing details. These issues threaten building safety and cut into investment returns. The humble solar hanger bolt often determines whether your roof system remains durable and leak-free.

This guide explains the real waterproofing challenges of solar hanger bolts and provides expert solutions for design, installation, and long-term maintenance. Whether you’re a solar professional, designer, or building owner, you’ll discover practical, reliable ways to maximize roof safety and system value.

2. Why Is Solar Hanger Bolt Waterproofing So Important?

2.1 Common Waterproofing Challenges with Through-Roof Installation

- Hanger bolts penetrate tile or metal roofing, making drill points prone to leakage over time.

- Different roof types have unique risks:

- Concrete tile roofs: Fragile edges and micro-cracks often cause leaks.

- Metal roofs: Frequent thermal expansion and contraction stress sealants and washers.

- Asphalt shingle roofs: Extreme temperatures require high-performance sealant.

2.2 Typical Consequences of Poor Waterproofing

- Structural damage: Wood beams rot, metal sheets rust.

- Higher energy costs: Wet insulation reduces building efficiency.

- Safety hazards: Indoor water can threaten electrical devices and people.

- Maintenance headaches: Frequent repairs boost owner and EPC workload.

3. Popular Waterproofing Solutions Compared

3.1 EPDM Waterproofing Gasket (Rubber Washer)

- UV, temperature, and weather resistant; reliable for most climates.

- Fits with M8/M10/M12 solar hanger bolts, providing the first line of defense.

- Cost-effective and easy to install.

3.2 Stainless Steel/Aluminum Metal Washers

- Adds compression, reducing failure from rubber washer deformation.

- Paired with EPDM for “dual-layer” waterproofing; boosts system lifespan to 15–20 years.

3.3 Silicone Sealant

- Flows into cracks around drilled holes, providing extra sealing for high rainfall or typhoon zones.

- Used as a secondary waterproofing layer for added security.

3.4 Integrated Waterproof Hanger Bolts

- Built-in waterproof cap and sleeve, providing all-in-one efficiency.

- Suited for large EPC solar projects.

4. Key Tips for Leak-Free Installation

- Drill size: Slightly smaller than the hanger bolt to ensure washer effectiveness.

- Placement: For metal roofs, install hanger bolts on ridges, away from water flow areas.

- Torque settings: Avoid over-tightening (damages washers) or under-tightening (weak seal).

- Washer fit: EPDM washers must lie flat and cover the hole entirely.

- Secondary sealant: Add extra silicone for extreme climate areas.

- Installer training: Ensure all staff follow the recommended procedures.

5. Waterproofing Strategies for Different Roof Types

Concrete Tile Roof

- Recommended: Hanger bolts + EPDM washers + waterproof cap.

- Use additional sealant for uneven surfaces or micro-cracks.

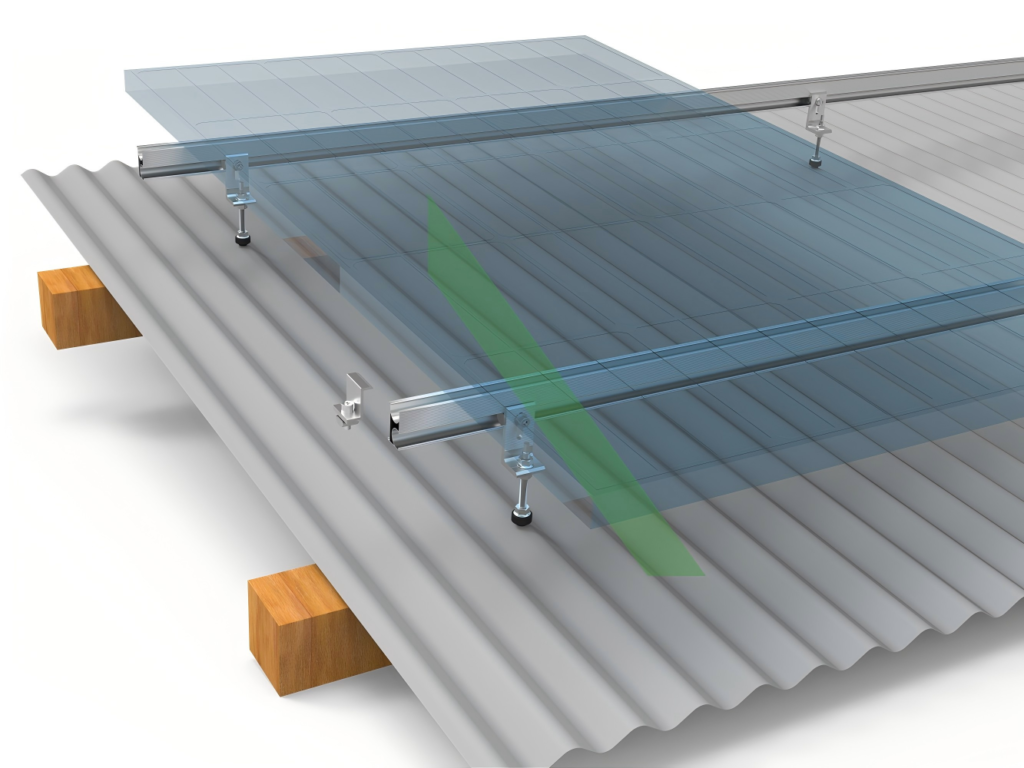

Metal Tile Roof

- Recommended: Thick EPDM washer + metal washer; install at ridges for best drainage.

Flat Roof / Color Steel Sheet Roof

- Recommended: PV bracket system with drainage design; optional waterproof membrane for maximum sealing.

6. Testing & Maintenance for Reliable Waterproofing

- Water spray test: After installation, spray water for 15 minutes to check for leaks.

- Annual inspections: Visually inspect washers and sealant at least once a year.

- Replacement cycle: EPDM washers last 10–15 years; replace if aging is noticed.

- Long-term reliability: High-quality solar hanger bolts support up to 25 years of operation.

7. FAQ

Q: How often should waterproof washers be replaced?

A: High-quality EPDM washers last 10–15 years. Replace whenever you see signs of aging.

Q: What are the common installation mistakes?

A: Washers not flush to the surface and wrong torque settings are typical errors; always follow installation guidelines.

Q: How to enhance waterproofing for extreme climates?

A: Use silicone sealant around EPDM or choose integrated waterproof hanger bolts.

Q: Does product selection affect waterproofing performance?

A: Yes. Select certified bolts and washers for best reliability and long-term benefits.

8. Conclusion & Next Steps

Waterproofing for solar hanger bolts is the foundation for any safe and profitable rooftop PV system. With smart design, quality materials, and careful installation, you can prevent leaks and ensure peace of mind.

If you need expert waterproofing solutions or high-grade hanger bolts, contact Suzhou Bolts. We supply residential, commercial, and utility-scale projects with one-stop products and technical support.

Secure your rooftop solar system for years to come! Explore our products and services, or ask our engineers for tailored advice. Your project’s success is our top priority.

As a professional supplier, Suzhou Bilateral Import & Export Co., Ltd. provides a full range of rooftop PV installation solutions, including:

- Solar Hanger Bolts (with EPDM waterproof gaskets, multiple specifications available, customizable upon request).

- Solar Roof Mounting Systems (compatible with flat roofs, pitched roofs, and various concrete tile, metal tile, and color steel sheet roofs).

- Solar Mounting Accessories (middle-clamps, side-clamps, rails, solar clamps, various stainless steel fasteners (such as screws, nuts, washers, bolts), etc.).

Our products have been widely used in residential, commercial, and large-scale PV power plant projects. Relying on high-quality raw materials and strict quality control, we provide customers with long-term, reliable support and waterproofing assurance.

Contact Information

PHONE/WAHTSAPP: +8613451556833

MAIL: sales@szbilateral.com