Introduction: Why Solar Hanger Bolts Matter

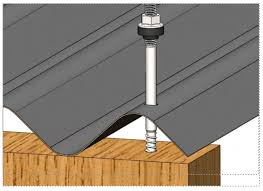

Solar hanger bolts are the backbone of pitched roof PV systems. They anchor your solar array securely, safeguard roof waterproofing, and support decades of reliable performance. But most leaks and system failures stem from basic installation errors. This guide spotlights those risks—and shows you how to avoid them.

Common Mistakes and Professional Solutions

1. Pilot Hole Errors

Mistakes:

- Wrong hole size (too small/large)

- Shallow drilling that won’t grip

- No pre-drilling—leads to cracked tiles

Pro Solutions:

- For wood purlins: Pre-drill holes just under the wood thread core size (M8 → 6–6.5mm, M10 → 7.5–8mm)

- For metal purlins:

- ≥2mm thick: Use self-drilling hangers

- ≤1.5mm: Use rivet nuts + machine bolts

- Special cases: Through-bolt with back-nut/washer

2. Waterproofing Mistakes

Mistakes:

- Ignoring EPDM washers

- Cheap sealant ages and cracks fast

- Uneven application causes leaks

Pro Solutions:

- Use three-layer protection: In-hole sealant + EPDM washer + external bead

- Choose butyl/polyurethane sealants with UV resistance ≥10 years

- Metal roofs need flexible sealant to handle expansion & contraction

3. Torque Issues

Mistakes:

- Too loose: Hanger bolts work loose in the wind

- Too tight: Threads strip, metal sheets deform

Pro Solutions:

- For wood: 25–35 N·m torque

- For metal: Refer to manufacturer (20–30 N·m typical)

- Don’t exceed torque specs for rivet nuts

- Always use a calibrated torque wrench and record tests

4. Wrong Fastening Methods

Mistakes:

- Applying wood-thread bolts straight into thin metal

Pro Solutions:

- Match bolt type to purlin

- Wood: Standard wood-thread

- Metal: Self-drilling, through-bolt, or rivet nuts + bolts

5. Material & Size Errors

Mistakes:

- Carbon steel rusts quickly

- Bolts too big damage structure; too small fail under wind

Pro Solutions:

- Use SUS304 for standard, SUS316 for coastal/corrosive zones, hot-dip galvanized (≥80µm coat) for economy

- Always check the manufacturer’s load charts

6. Improper Tools

Mistakes:

- Pliers damage threads

Pro Solutions:

- Use a double-nut method or a dedicated solar bolt driver

Quick Comparison: Wood vs Metal Purlins

| Item | Wood Purlins | Metal Purlins |

|---|---|---|

| Fastening | Wood-thread bolts | Self-drill/Rivet/Through-bolt |

| Drilling | Pre-drill required | Self-drill or rivet nut hole |

| Waterproof | Sealant + EPDM | EPDM + flexible sealant |

| Torque | 25–35 N·m | Lower, controlled |

| Inspection | Pull-out/torque | Rivet nut/waterproof check |

Economic Impact

Every faulty bolt can add 15–20 minutes of labor; rework can increase install costs by 8–12%. Get it right the first time to cut labor and O&M expenses by 10–15%.

Standards & Testing

- DIN 976/DIN 7995: Fastener threads

- EN 1090: Structure compliance

- UL 2703: PV mounting

- ASTM E488: Pull-out test

- Check with pull/torque/waterproof tests after install

Quick Installation Steps

- Identify the roof type and purlin

- Mark drill points—avoid cracks

- Pre-drill (wood) or self-drill (metal)

- Seal inside the hole

- Insert bolt + EPDM washer

- Tighten to spec

- Apply external sealant

- Fit the bracket and rail

- Inspect alignment, torque, and waterproofing

Industry Trends

- BIPV: Aesthetic & high waterproofing required

- Lightweight roofs: Specialized fasteners needed

- Europe: Certifications and waterproofing are top priorities

- Southeast Asia: Robust sealing for heavy rainfall

- Middle East: Thermal tolerance crucial

About Us

Suzhou Bilateral Import & Export Co., Ltd. specializes in solar mounting systems and stainless steel fastener solutions. Our key products include:

- Solar Hanger Bolts (304/316 stainless & hot-dip galvanized)

- Mounting systems for cement and metal tiles

- Full range of PV accessories

Learn more: www.szbolts.com

Conclusion

Solar hanger bolts make or break the strength and waterproofing of pitched roof PV systems. Avoid common mistakes—drill, waterproof, torque, and fasten with confidence—so your project remains safe and reliable for decades.

Partner with Suzhou Bilateral for high-quality products, technical expertise, and hassle-free support.