When it comes to building stable, long-lasting solar mounting systems, choosing the right foundation is just as important as selecting solar panels or inverters.

For projects installed on slopes, sandy soil, or rocky ground, traditional concrete foundations can be time-consuming, costly, and environmentally intrusive.

That’s where ground screws for solar mounting systems come in — a fast, flexible, and eco-friendly solution for any terrain.

What Are Ground Screws?

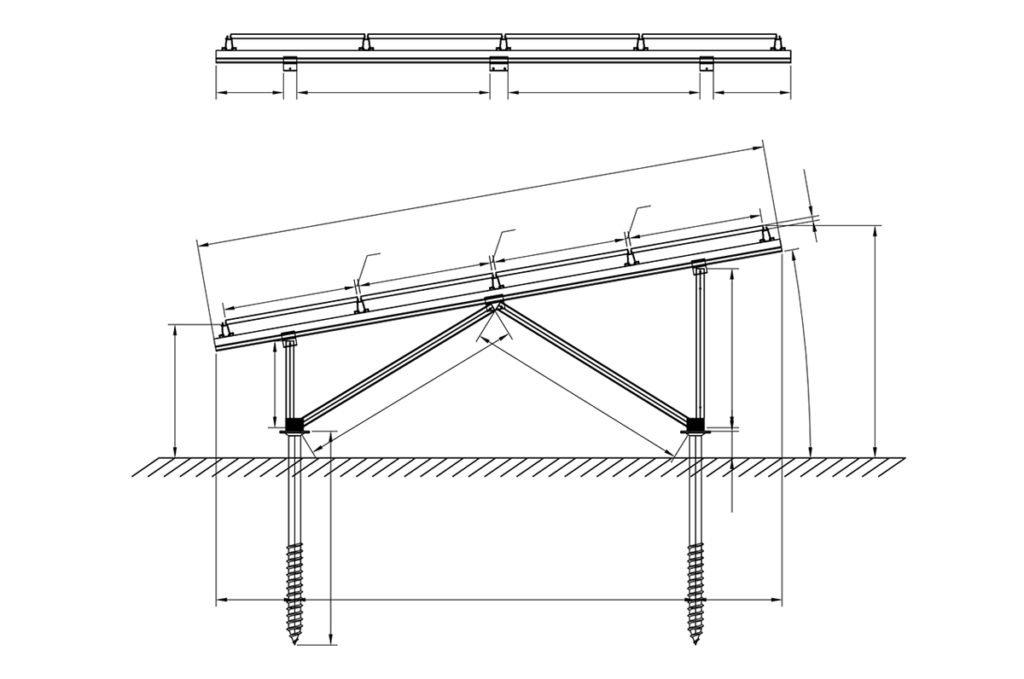

Ground screws, also known as solar screw piles or helical piles, are steel anchors that are driven into the ground without the need for excavation or concrete. These specially designed solar ground anchors feature a spiral blade that allows the screw to cut through soil and provide a secure base for various solar mounting systems.

Instead of pouring concrete and waiting days for it to cure, installers can complete ground screw installations in a matter of hours. This makes them ideal for PV mounting systems on uneven terrain or in time-sensitive solar projects.

Why Ground Screws Are Ideal for Solar Mounting

Whether you’re developing a large solar farm or a small off-grid system, ground screws offer multiple advantages over traditional foundations:

1. Fast Installation with No Concrete

Ground screws are pre-engineered for quick deployment. With the right equipment, they can be installed in minutes. There’s no need for drying or curing time, making them perfect for remote or time-sensitive solar installations.

2. All-Terrain Compatibility

Ground screws can be installed in:

- Sandy soil

- Clay or loam

- Rocky terrain

- Sloped or uneven ground

- Frost-prone or coastal areas

They are excellent for ground-mounted solar systems in rough terrain where excavation is difficult or environmentally harmful.

3. Eco-Friendly and Reusable

Ground screws leave minimal environmental impact. They don’t disturb the soil structure, require no water, and produce no concrete waste. When a solar system needs to be relocated or upgraded, the screws can be removed and reused.

4. High Durability and Load Capacity

Made from hot-dip galvanized steel or stainless steel, ground screws resist corrosion and can withstand strong wind or snow loads. Properly installed, they can last 25+ years, making them ideal for long-term PV installations.

Compatible with All Types of Solar Mounting Structures

Ground screws are fully compatible with:

- Fixed tilt ground mount systems

- Single post and double post frames

- Seasonal adjustable solar racks

- Solar tracking systems

They support flexible designs and layouts for residential, commercial, or utility-scale solar projects.

How to Choose the Right Ground Screws

The best solar ground screw depends on your project’s soil type, load requirements, and system design. Key factors include:

| Specification | Description |

|---|---|

| Length & Diameter | From 500mm to 3000mm |

| Helix Size & Shape | Custom-designed for different soil types and load-bearing requirements |

| Material | Hot-dip galvanized steel or SUS304 / SUS316 stainless steel |

| Connection Flange | Pre-drilled to match various solar racking systems |

Professional soil testing is recommended to determine pullout strength and load-bearing capacity.

Why Choose Suzhou Bilateral Ground Screws?

Suzhou Bilateral is a trusted manufacturer of stainless steel fasteners and solar mounting hardware. With over 12,000 sqm of factory space and monthly output of 5 million+ pieces, we deliver reliable, certified products to global customers.

Our advantages:

- ISO, CE, and RoHS certified

- Full range of solar ground mounting screws

- Support for OEM & ODM customization

- Global shipping and fast production cycles

- Solutions for all soil and climate conditions

Ready to Build on Solid Ground?

If you’re looking for a reliable, eco-friendly, and cost-effective solution for your solar mounting foundation — ground screws are the answer.

Whether you’re working on sandy ground, rocky terrain, or frozen soil, Suzhou Bilateral can provide the right screw pile for your project.

Contact us today to get a free consultation or quote.

Visit our website: www.szbolts.com

Contact Email: sales@szbilateral.com