1. Introduction

As solar energy adoption accelerates worldwide, the spotlight increasingly shifts from just panel efficiency to the lasting reliability and durability of mounting systems. While panels often take center stage, it’s actually the quality and performance of fasteners—especially solar hanger bolts—that quietly safeguard the structural security needed for PV installations to last decades.

The global solar fastener market was valued at $3.4 billion in 2024 and is projected to reach $5.2 billion by 2030 (CAGR 7.2%). Notably, the Asia-Pacific region drives over 45% of global demand, led by major installations in China, India, and Japan. This article reveals the most recent market trends, competitive dynamics, and technical innovations shaping the industry’s future.

2. Market Structure and Product Classification

A solar mounting system comprises two major functional layers: solar fasteners and solar accessories, each playing distinct roles:

Solar mounting systems are built on two core layers: solar fasteners, which form the mechanical backbone and carry the system’s load, and solar accessories, responsible for supporting and securing PV modules.

- Solar Fasteners:

- Solar Hanger Bolts: Secure mounting systems to wooden or metal rooftops

- Screws, Nuts, Washers: Ensure tight, stable connections

- Anchor Bolts: Used for ground-mounted systems

- Solar Accessories:

- Clamps (Middle/End): Fix PV modules in place

- Rails: Support and optimize load distribution

- Roof Hooks, Brackets, L-feet, Grounding Clips: Adapt to diverse roof structures, offer electrical continuity

Classification is key: solar hanger bolts are fasteners, not accessories, ensuring reliable supply chain analysis and project planning.

3. Market Drivers

- Accelerated Global PV Installations:

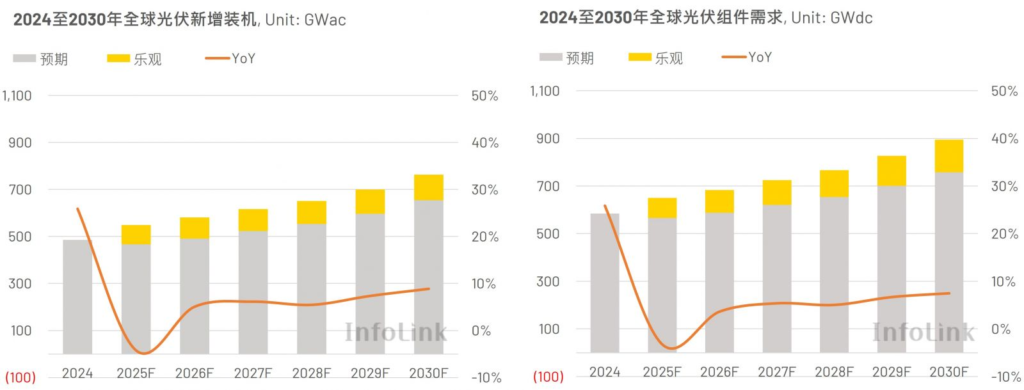

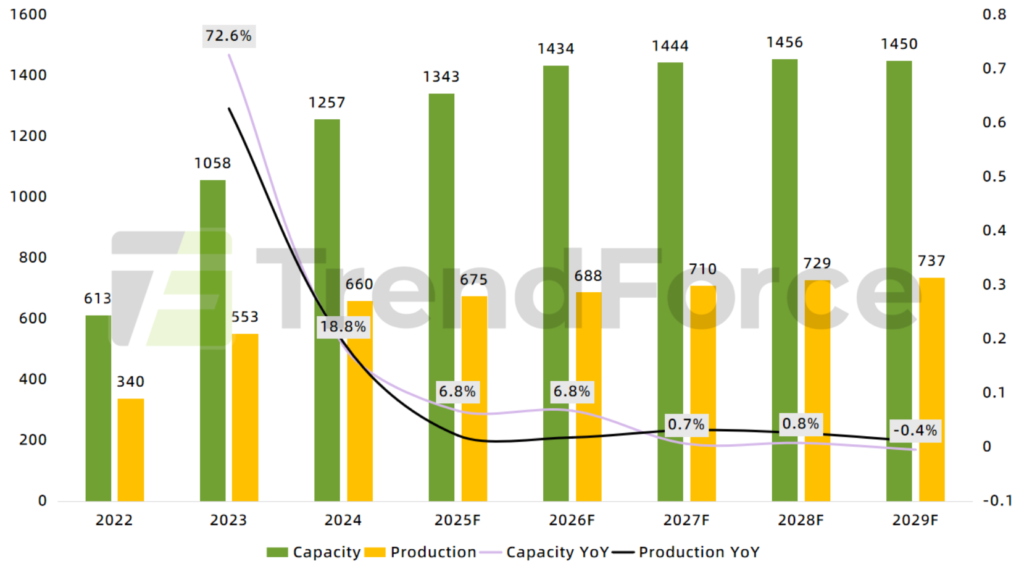

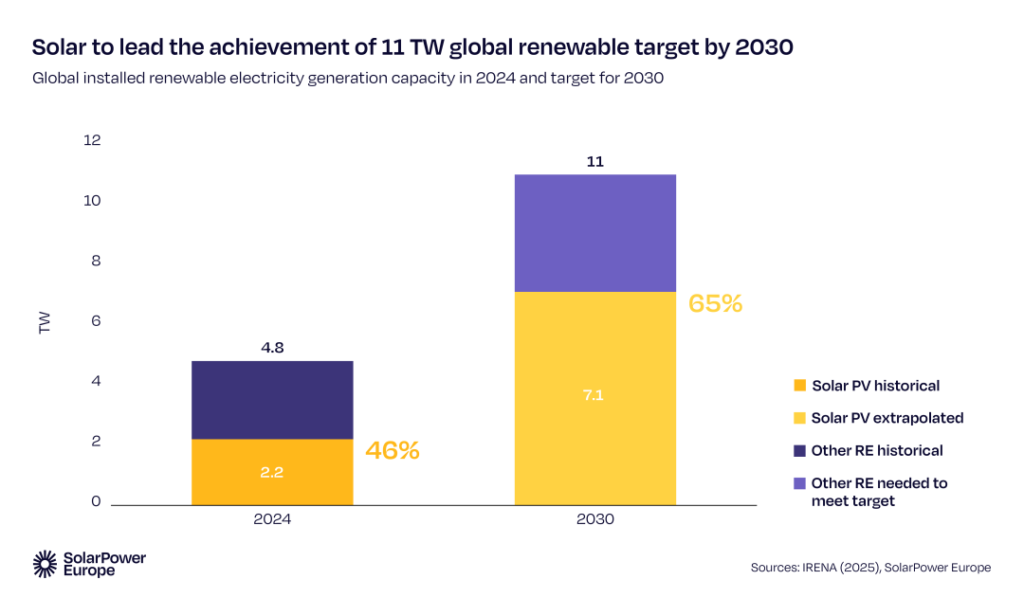

In 2024, global installed PV capacity reached 420 GW (up 17% YoY), massively driving demand for all types of fasteners. - Rise of Distributed Rooftop Systems:

Almost 40% of new capacity in Europe, Japan, and the US comes from distributed projects, requiring flexible and waterproof hanger bolts—especially SS304/316. - Advancements in Material & Manufacturing:

Stainless steel fasteners offer corrosion resistance and withstand wind loads. Advanced cold heading and precision machining elevate accuracy, consistency, and performance. - Policy Incentives:

Targets like China’s, India’s, and the EU’s “REPowerEU” are set to add over 100 GW by 2025, guaranteeing continued market expansion.

4. Regional Market Overview

| Region | 2024 Market Size | 2025–2030 Growth | Key Drivers |

|---|---|---|---|

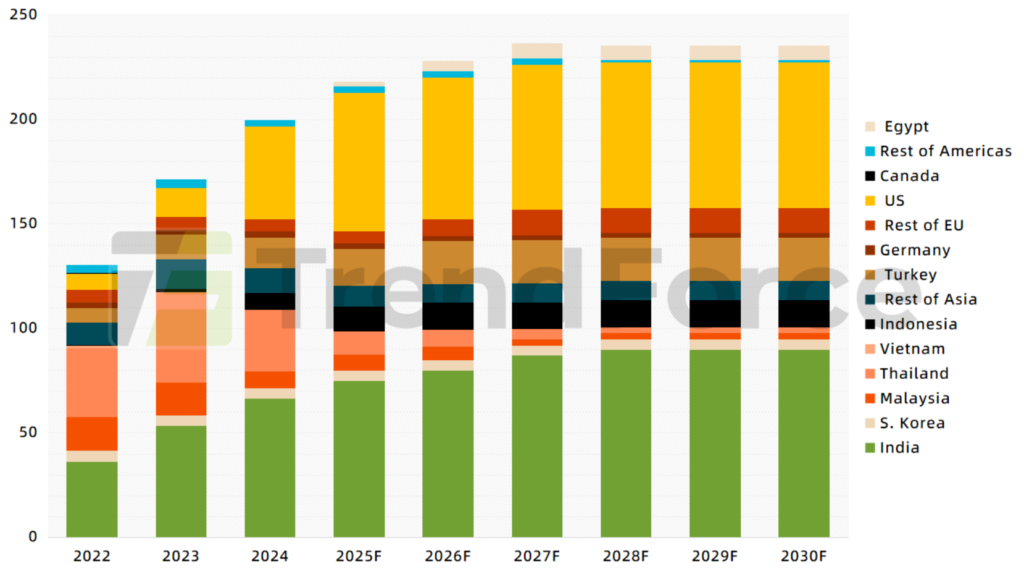

| Asia-Pacific | $1.3B | 9.1% CAGR | Cost advantage, high install volumes |

| Europe | $1.2B | 6.5% CAGR | Mature market, strict standards |

| North America | $0.9B | 7.2% CAGR | Incentives, rooftop projects |

| Middle East & Africa | $0.4B | 8.4% CAGR | Ground installs, harsh climate |

| Latin America | $0.2B | 7.0% CAGR | Policy-driven, limited manufacturing |

Conclusion: Asia-Pacific leads global production, while Europe and North America dominate high-end system applications.

5. Competitive Landscape

The solar fastener industry is moving from price wars to technology-driven solutions.

- Upstream (Materials, Coatings):

Aperam, Outokumpu deliver stainless steel; MacDermid Enthone provides advanced coatings. ESG drives recycled, low-carbon sourcing. - Midstream (Manufacturers):

Würth, Hilti, and Bossard focus on high-quality fasteners; Chinese, Indian, and Vietnamese OEMs dominate volume with competitive pricing. The industry transitions to system-based, high-performance fastener solutions. - Downstream (Brands, EPCs):

European leaders (K2, PMT, Mounting Systems) and international integrators (IronRidge, Clenergy) expand modular and integrated mounting options. Asia’s local OEM/ODMs increasingly link with EPCs on global projects.

Industry trend: stronger collaboration between manufacturers and system brands—customized solutions for greater installation efficiency and reliability.

6. Future Outlook

By 2030, solar fastener demand will exceed 18 billion units/year, with hanger bolts making up 28%. Leading directions include:

- Lighter, more optimized structures

- Advanced materials like duplex stainless steel and nickel alloys

- Enhanced corrosion resistance and life-cycle structural monitoring

7. Company Profile and Strategic Positioning

High-quality fasteners are crucial for PV safety.

Suzhou Bilateral Import and Export Co., Ltd. specializes in solar mounting solutions, providing:

- Solar Mounting Systems: Roof and ground solutions

- Solar Hanger Bolts: High-strength, waterproof designs

- Clamps, Rails, Brackets, Screws, Nuts, Washers

With robust international experience and strict quality control, Bilateral delivers compatible, reliable products to residential, commercial, and utility-scale PV markets.

For lasting reliability and performance—choose partners with proven expertise in solar fasteners and mounting systems.

Learn more: www.szbolts.com

MAIL: sales@szbilateral.com

Conclusion

The future of the global solar fastener market is defined by quality, innovation, and system-specific solutions. From stainless steel hanger bolts to custom-engineered mounting accessories, every choice impacts safety, durability, and project return. Working with experienced suppliers like Suzhou Bilateral helps EPCs and developers secure efficient, durable installations. As solar energy continues expanding, investing in high-quality fasteners means investing in the long-term success of your renewable projects.

Ready to optimize your PV system? Contact us or request a quote. Let’s build sustainable energy together.