Rooftop PV systems are rapidly becoming the preferred choice for energy-saving upgrades. By 2030, more than half of distributed PV systems will be on pitched roofs with concrete or metal tiles. The solar hanger bolt is the key connector in these systems—ensuring mounting security and weather resistance for 20–30 years.

Selecting the wrong hanger bolt size can result in loose panels, roof leaks, or even serious safety risks. This guide draws on engineering standards and real-world cases to help you make the best choice for your roof. I’ll combine practical cases and engineering standards to help you make a scientific decision.

Key Specifications for Solar Hanger Bolts

Diameter:

M12: Heavy-duty, for metal tiles, large/commercial roofs, high wind/snow loads.

Note: For wind pressures >0.8 kN/m², use M12.

M8: Lightweight, small residential roofs.

M10: Most common, for concrete tile roofs, balances strength and ease.

Length:

- Must penetrate roof covering and embed 40–60mm into rafters/purlins.

- Concrete tile (typical): ≥200mm; Metal tile: 120–150mm with larger diameter for strength.

Thread Type:

Wood thread for timber rafters;

Machine thread for bracket mounting;

Self-drilling for metal purlins—no pre-drilling needed.

Material:

- SUS304 for standard residential.

- SUS316 for coastal/industrial/climates.

- Avoid low-cost galvanized steel for long-term PV investment.

Matching Bolt Size to Roof and Tile Type

The selection of the hanger bolt size is closely related to roof thickness and tile type.

Common Roof Scenarios

| Roof Type | Covering Thickness | Recommended Bolt Length | Notes |

|---|---|---|---|

| Concrete Tiles | 20–40mm | 200–300mm | Thick tiles, use with L-feet |

| Metal Tiles | <10mm + purlin | 100–200mm | Self-drilling, waterproofing needed |

| Flat Tiles | 10–20mm | 200–250mm | Common in Europe |

| Asphalt Shingles | 5–10mm + board | 100–200mm | Prevalent in North America |

Selection Logic

Concrete Tile Roof → Focus on “penetration capability,” requiring long bolts + L-feet brackets.

Metal Tile Roof → Focus on “pull-out strength,” emphasizing diameter and sealing performance.

Application Differences: M8 vs. M10 vs. M12

| Model | Load Capacity | Typical Application | Advantages | Limitations |

|---|---|---|---|---|

| M8 | Low | Small residential pitched | Quick install, small holes | Not for high wind/snow |

| M10 | Medium-High | Mainstream concrete roofs | Good strength, easy install | May not suit extreme conditions |

| M12 | High | Metal/commercial/large | Max load, harsh climates | Needs larger holes, pro install |

Practical Application Experience:

European Residences: Mostly use M10;

Southeast Asian Coastal Commercial Projects: Often use M12;

North American Lightweight Asphalt Shingle Roofs: M8 still has significant application space.

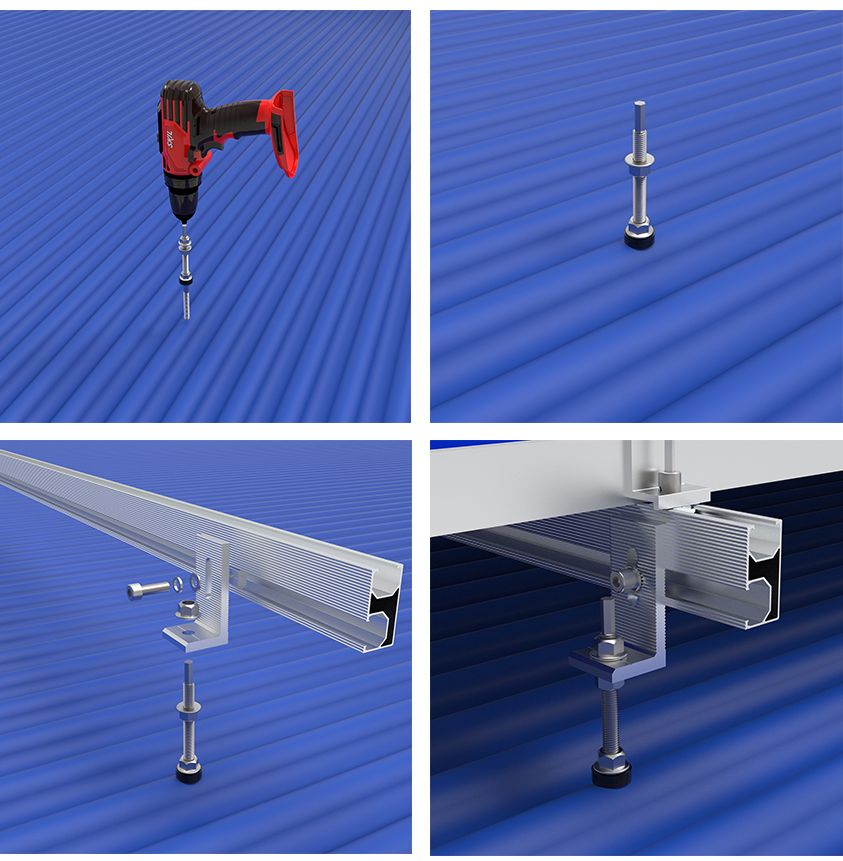

Installation Precautions and Risk Mitigation

Installation Tips and Risk Prevention

- Locate rafters/purlins: Use a stud finder for solid fixing.

- Pre-drill for wood: Prevent splitting, ensure alignment.

- Waterproof properly: Use EPDM washers, sealant, and flashing.

- Control torque: Avoid over- or under-tightening.

- Common pitfalls:

- Not reaching the load-bearing structure

- Skipping waterproofing

- Using inferior materials

- Recommendation:

- For mid/large projects, get a structural engineer’s review.

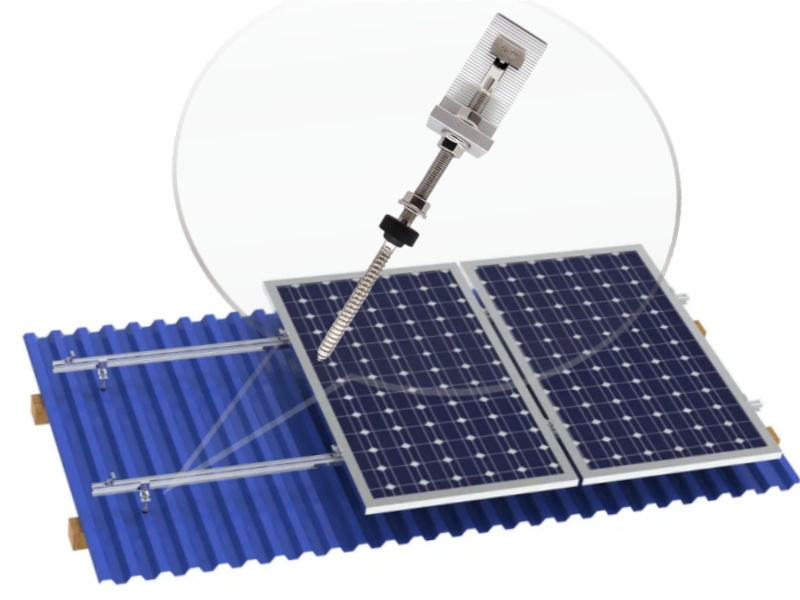

The Role of Hanger Bolts in Pitched Roof Mounting

Hanger bolts do more than just secure components—they transfer mechanical loads and act as a vital waterproof barrier, protecting the longevity of your rooftop solar system.

Forming a complete structure.

Concrete Tile Roof System: Bolt penetrates the tile → fixed to the rafter → connects to L-feet and rails.

Metal Tile Roof System: Bolt goes directly through the tile surface → fixed to the purlin → used with a waterproof cap, forming a reliable waterproofing system.

This means the hanger bolt is not just a fastener, but a core component for “mechanical load transfer” and “waterproof barrier” in the pitched roof system.

Conclusion

Choosing the correct solar hanger bolt size (diameter, length, and material) is crucial for ensuring safe, stable, and weatherproof pitched roof PV installations. Match your bolt to the roof type, tile thickness, and system design for optimal results—making bolt selection a crucial part of overall solar project success.

M8 → Lightweight residential projects;

M10 → Mainstream concrete tile roofs;

M12 → Metal tile roofs, large commercial projects, and high wind load areas.

About Us

Suzhou Bilateral Import & Export Co., Ltd, As a professional supplier of solar mounting systems and stainless steel fasteners, we provide global customers with:

A full range of Solar Hanger Bolts (M8/M10/M12), compatible with concrete and metal tile roofs;

Components for pitched roof mounting systems like L-feet, rails, mid-clamps, end-clamps;

Integrated solutions for both rooftop and ground-mounted PV mounting systems.

Our products have been widely used in residential, commercial, and large-scale ground-mounted power plants, and exported to markets in Europe, North America, Southeast Asia, etc.

Learn more by visiting our website: www.szbolts.com