Are you unsure how to choose the right solar hanger bolt for your rooftop PV system? The substrate, structure, and installation complexity all affect system strength and waterproofing. Selecting the wrong model can shorten the system’s lifespan and lead to leaks or safety hazards. Efficient selection and installation are essential for engineers and homeowners alike.

This article deeply analyzes the main types of solar hanger bolts—their head shape, thread type, and typical applications. You’ll learn to distinguish key features, avoid common mistakes, and deliver lasting, robust, and safe rooftop solar projects.

I. Classification by Head Type

1. Sharp-Point Self-Tapping Type

Applications:

- Suitable for most wooden beams.

- It can be directly screwed in without pre-drilling.

- Commonly uses ST8 threads. For softwood, ST3/8 threads with pre-drilled pilot holes are recommended to prevent cracking.

Features:

- The tip is sharp, similar to a wood screw.

- Can be driven into wood or softer purlins, usually without pilot holes (or only a small guide hole).

- Bottom has coarse wood threads; top has fine machine threads for bracket connection.

Advantages:

- Quick installation: Self-tapping tip enables fast screwing into wood.

- Cost-effective: Simple structure, relatively low manufacturing cost.

- Suitable for soft substrates: Works well with wooden beams, pine roofs, etc.

Limitations:

- Not effective for hardwood or metal purlins; may be difficult to screw in or damage the tip.

- May cause cracking in brittle wood.

2. Drill-Tip Self-Drilling Type

Applications:

- Specifically designed for metal beams.

- Can drill directly into metal without pre-drilling.

- Not recommended for wood, as high heat during drilling may char the wood and damage the bolt.

Features:

- Drill-shaped tip, similar to a self-drilling screw.

- Can drill and anchor directly into metal purlins; suitable for steel roof structures.

- Thread layout is the same as other hanger bolts (coarse lower threads, fine upper threads).

Advantages:

- One-step operation: Combines drilling and fastening in one.

- Highly efficient: Ideal for large-scale steel roof installations.

- Strong connection: Drill tip ensures high load capacity.

Limitations:

- Higher manufacturing cost.

- Not suitable for wood substrates.

- Poor material or heat treatment may lead to wear or breakage.

3. Flat-End Type

Applications:

- Theoretically suitable for various substrates, but pre-drilling is always required.

- Cannot self-tap; must be screwed into a pre-drilled hole.

Subtypes:

a) Smooth Flat-End (No Relief Groove)

Applications:

- Wooden roof PV installations.

- Lightweight steel roof PV systems.

- Scenarios requiring precise hole alignment and infrequent disassembly.

Advantages:

- High load capacity: Fine upper threads ensure even stress distribution and long-term stability.

- Easy installation: Flat-end facilitates alignment with pre-drilled holes.

- High structural strength: Continuous rod section without grooves enhances load capacity.

- Wide applicability: Works for wooden pitched roofs or timber-truss supported PV systems.

Notes:

- Ensure precise hole size to prevent thread binding.

- Torque tools are recommended for uniform depth.

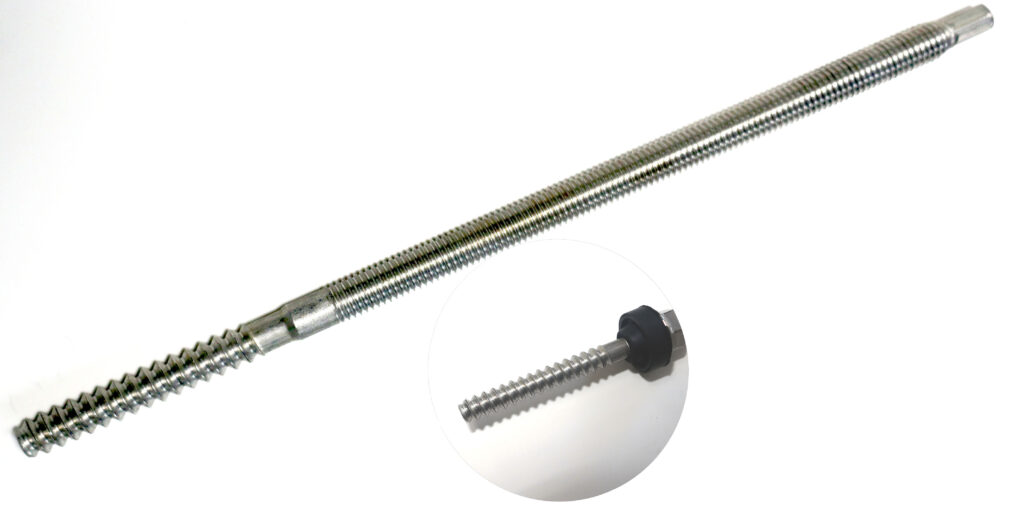

b) Slotted Flat-End (T-Thread, With Relief Groove)

Features:

- The lower end features a slotted flat wood thread (T-thread), while the upper end has fine machine threads with a relief groove.

- Relief groove improves screwing smoothness and prolongs thread life.

Advantages:

- Smooth insertion: T-slot slightly cuts wood fibers during screwing, reducing resistance.

- High load-bearing: Relief groove distributes stress evenly.

- Fatigue and vibration resistance: The Groove helps absorb stress, extending the lifespan.

- Convenient installation: Reduces pre-drilling effort and precision requirements.

Applications:

- Wooden roof PV installations.

- Light-to-medium steel roof PV systems.

- Scenarios requiring smoother installation and improved fatigue resistance.

Notes:

- Hole alignment is still critical to avoid angled insertion or substrate damage.

- Power tools or torque wrenches are recommended for consistent depth.

c) General Flat-End (With Relief Groove)

Features:

- The flat end reduces substrate damage and evenly distributes contact stress.

- Relief groove releases stress during insertion, preventing wood cracking or metal deformation.

- Double-thread: coarse lower thread anchors into substrate; fine upper thread connects bracket.

- Usually made of stainless steel (e.g., A2-70, A4-80) for outdoor durability.

Advantages:

- Safer installation: Groove reduces cracking and roof leakage risk.

- Stable structure: Double-thread ensures anchor and bracket stability.

- Good waterproofing: Compatible with EPDM washers for long-term sealing.

- Weather resistance: Stainless steel withstands heat, humidity, and corrosive environments.

- Wide applicability: Wood, steel purlins, and tile roofs.

d) Chamfered Flat-End (Conical, With Relief Groove)

Features:

- Flat-end with chamfered edges for easier alignment with pre-drilled holes.

- Chamfer provides slight guidance, reducing slipping or misalignment.

Applications:

- Wood roofs, plywood, light steel structures, especially where hole edges are irregular or prone to splitting.

e) Shoulder Flat-End (Blunt Flat with Relief Groove)

Features:

- Blunt flat tip prevents substrate damage and increases contact area for even stress.

- The shoulder between the flat-end and threads disperses insertion pressure.

- Relief groove reduces stress during insertion.

- Double-thread: coarse lower for anchoring, fine upper for bracket connection.

- Durable stainless steel (A2/A4) with corrosion resistance.

Advantages:

- Excellent anti-cracking: Shoulder and groove reduce substrate cracking risk.

- Even stress distribution: Extends roof lifespan.

- Good sealing: Works with waterproof washers for long-term sealing.

- Versatile: Suitable for wood, metal purlins, etc.

- Reliable installation: Double threads ensure a stable connection.

II. Classification by Thread Type

1. Coarse Thread (Wide Thread)

Applications:

- Mainly for wood, matching the substrate’s physical properties.

Advantages:

- Strong grip: Larger pitch engages wood fibers securely.

- Fast screwing: A Larger lead per turn increases efficiency.

- Reduces cracking: Smaller fiber-cutting area lowers stress concentration.

- Accommodates wood expansion/contraction.

2. Fine Thread (Machine Thread)

Applications:

- For metal profiles or high-strength connections.

Advantages:

- High tensile and load capacity: More threads per length ensure even stress.

- Easy micro-adjustment: Small lead allows precise alignment.

- Anti-loosening: Tight engagement improves vibration resistance.

- Fatigue resistance: Even stress distribution under repeated loads.

III. Classification by Application

- Wood beams: Sharp-point coarse threads (self-tapping) preferred. ST8 commonly used; ST3/8 with pre-drilled pilot holes for softwood.

- Metal beams: Fine threads preferred. Options include sharp-point fine threads (pre-drilled guide holes) or flat-end fine threads (pre-drilled). Drill-tip self-drilling types do not require pre-drilling.

IV. Comparison Table of Common Solar Hanger Bolt Types

| Type | Substrate | Installation | Main Advantages | Recommended Scenario |

|---|---|---|---|---|

| Drill-Tip Self-Drilling | Metal | No pre-drilling | Fast, high-strength | Steel roofs, large-scale PV |

| Sharp-Point Self-Tapping | Wood | No/pre-drilled | Quick, anti-crack | Timber purlins, softwood |

| Flat-End w/ Relief Groove | Wood/Steel | Pre-drilled | Uniform force, waterproof | Complex/high-strength roofs |

| Shoulder Flat-End | Wood/Steel | Pre-drilled | Pressure spread, anti-crack | Premium projects, waterproofing |

- Drill-tip: For metal beams only; do not use in wood.

- Self-tapping wood thread (sharp-point): Directly screws into wooden beams, low risk of cracking. Pre-drill recommended for softwood.

- Universal (steel structure type): Can be used in metal and wood, requires pre-drilled holes.

- Without relief groove: Continuous threads, slightly higher strength, higher friction, requires precise hole and nut matching; suitable for high-precision, high-strength applications with torque tools.

- With relief groove: Reduces stress concentration, decreases insertion resistance, prevents thread binding, improves load uniformity and fatigue resistance; safer, more convenient installation, highly reliable long-term; recommended for steel structures, solar brackets, heavy-duty connections.

V. Selection & Key Installation Advice

- Clarify substrate (wood/steel/hybrid) and choose accordingly.

- Consider load, durability, and waterproofing needs.

- Use stainless steel (A2-70/A4-80) for corrosion resistance.

- Relief groove and shoulder types are preferred for long-term stability and sealing.

Conclusion

Regardless of structure or material, solar hanger bolts are the backbone of safe, long-lasting PV installations. Smart selection and proper installation deliver the best system reliability and maximize your green energy investment.

Suzhou Bilateral specializes in premium solar mounting systems and hanger bolt solutions. For selection advice or turnkey procurement, contact our engineering team—let every fastening detail safeguard your rooftop project.

At Suzhou Bilateral Import & Export Co., Ltd., a company committed to offering one-stop solar panel mounting solutions and accessories to you.

Discover more in our Solar Mounting Products Catalog or request a free consultation today.

Suzhou Bilateral Import & Export Co., Ltd. specializes in solar mounting systems and fasteners, with a focus on solar hanger bolts. Made of premium stainless steel, our products feature high strength, corrosion resistance, and easy installation. Widely applied to wooden beams, steel structures, and rooftop PV systems, they deliver reliable and durable fastening solutions for global customers.

Contact us

Phone/WhatsApp: +86 13451556833

Mail: sales@szbilateral.com